Philosophy

Our aim is customer satisfaction

In all our activities we are anxious to achieve highest perfection. However, we don’t want to set standards at technologies and innovations only, but we also offer the best performance to our employees – they are the key resource for the success of our company and we wish that they are proud to work for IPP Pump Products GmbH. All this should help us to continue to grow profitably and to inspire our customers. Our activities are guided by four goals:

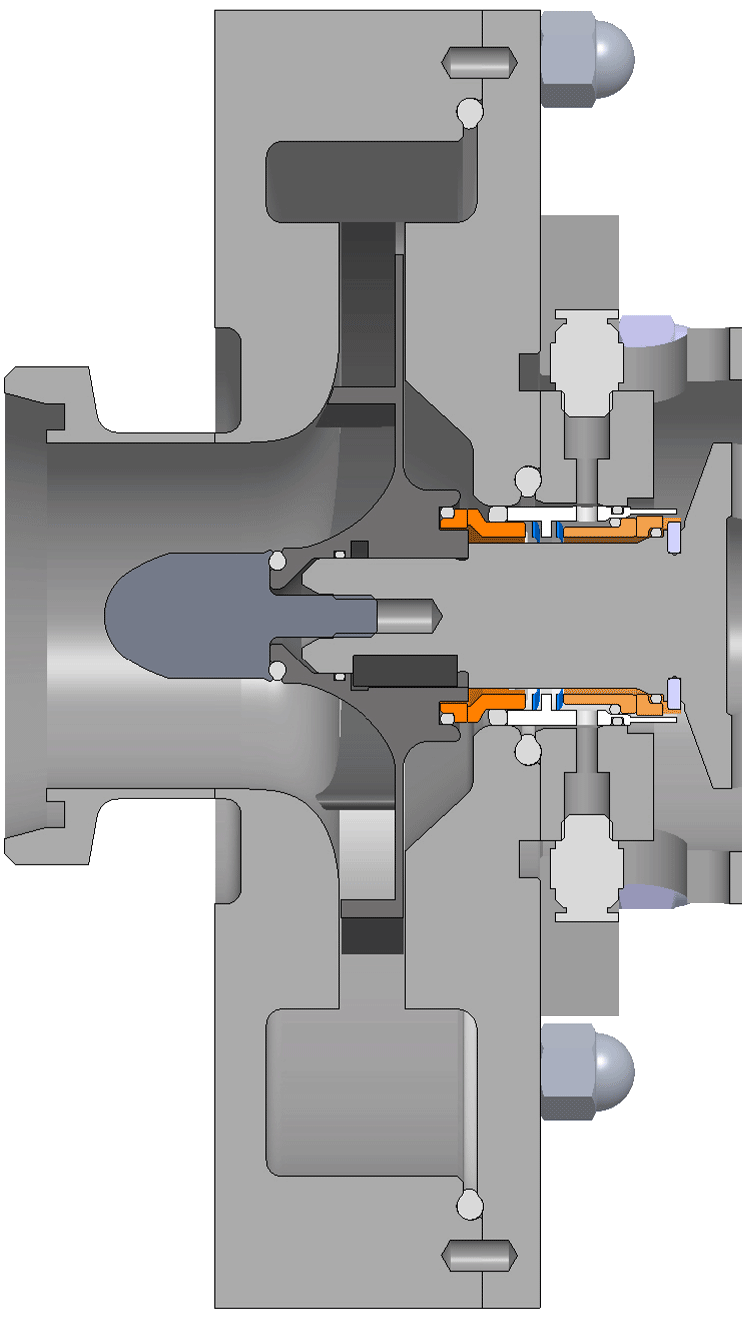

1. Leading in technology and innovation

We set standards at technology and innovation – due to the extensive experience of our employees the core competence is in the field of rotary lobe pumps. Here we take advantage of the potentials of an in-house machining technology as well as of innovative laser welding procedures. In relation to the use of digital technologies we want to be the leader both with our products and with the contact to our customer.

2. Inspired customers

More and more producers decide for an ipp pump. With excellent products we create value for our customers. With regards to customer satisfaction we strive towards to be at the top in any relevant evaluation and to convince again and again with the excellent quality of our products. Besides the worldwide distribution of our excellent pumps we also want to inspire our customers with a customized and first-class After-Sales service.

3. First class teams

Our employees are proud to work at ipp Pump Products. We work in teams where competence and team spirit have priority. The four corporate values enthusiasm, appreciation, integrity and discipline are the basis of our action.

Integrity has a special significance for our company. It guides our actions in relation to employees, the company, business partners and customers. We are convinced that doing business with integrity makes us more successful in the long term and benefits society at the same time.

4. Excellent price performance ratio

Attractive products, short delivery times, good logistics and competence form important links of a network. The high performance of ipp Pump Products GmbH always results in an excellent price performance ratio.

Contact person

Thomas Moldenhauer

Managing Director

+49 5439 80921-0

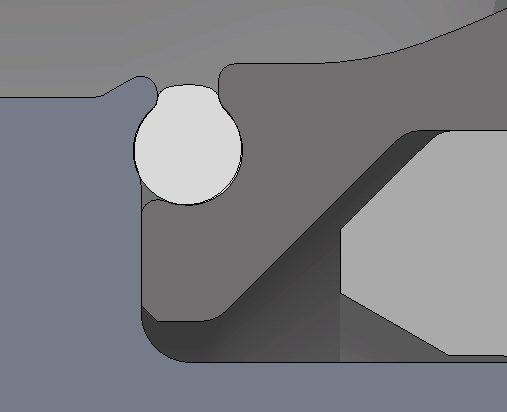

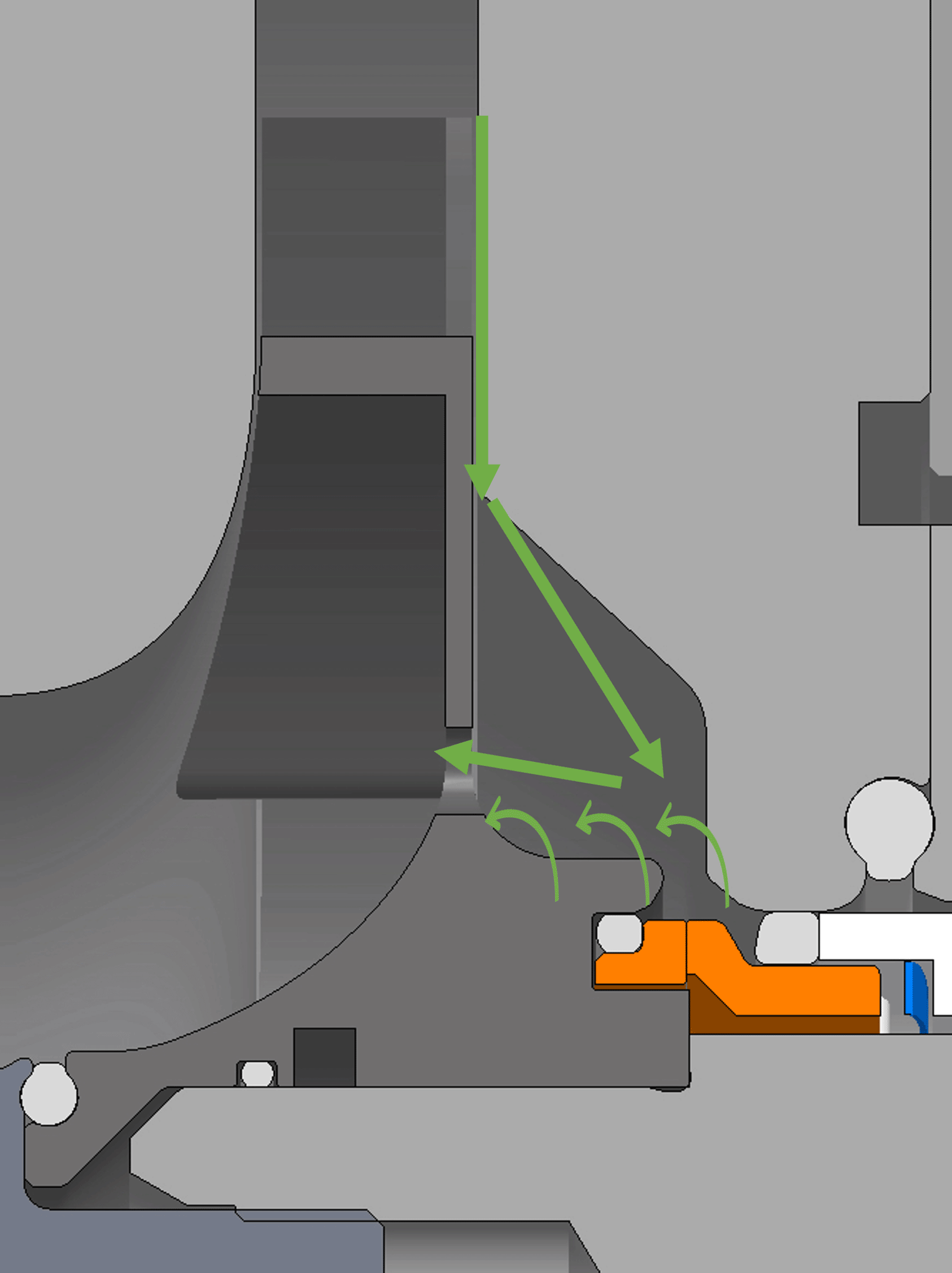

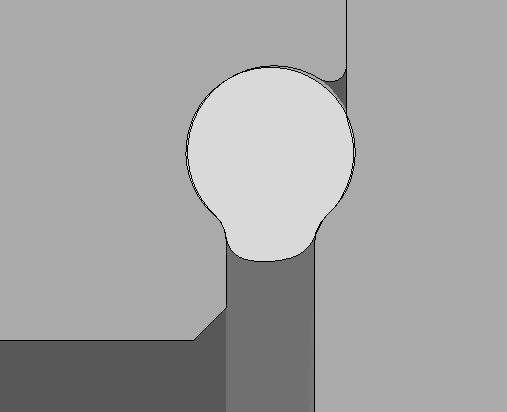

O-ring cover housing

O-ring cover housing