Progressive cavity pumps Discharge pumps for Fluidbag & barrels

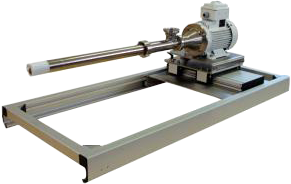

Fluid bag pumps

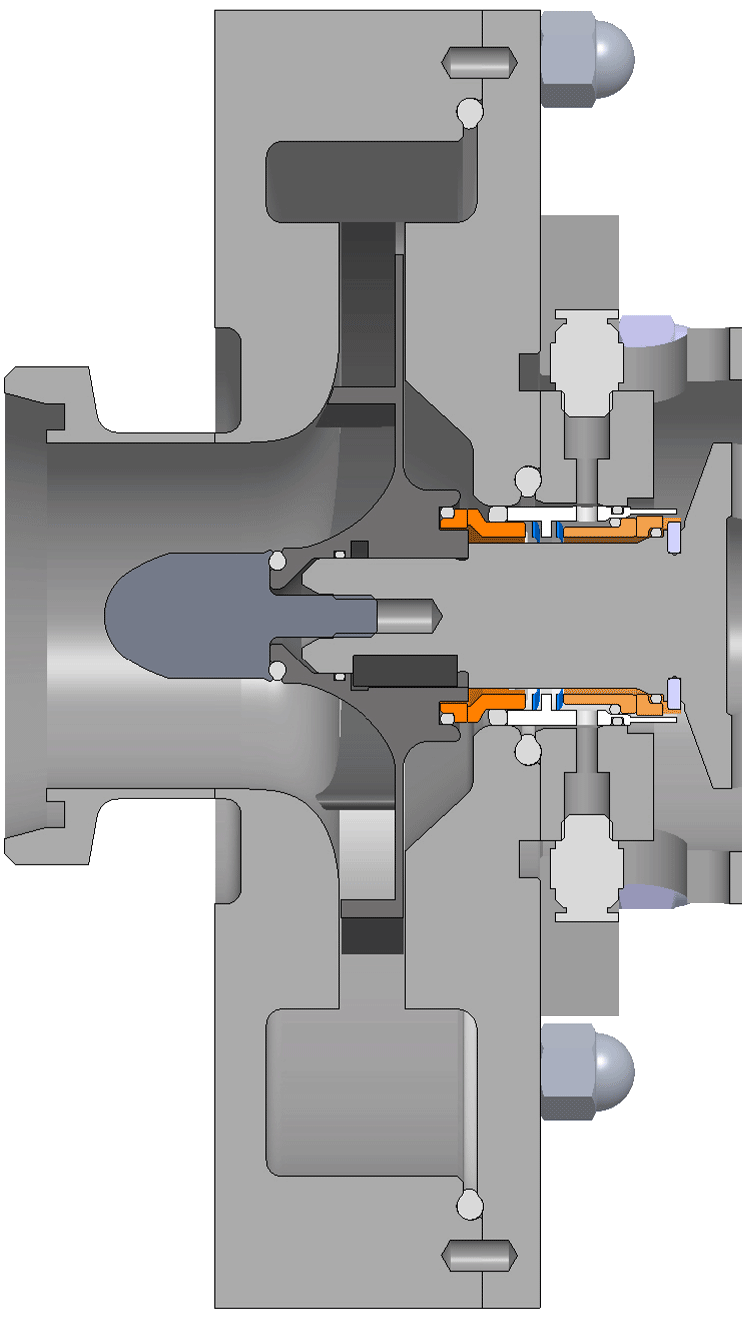

- Pharmaceutical compliant design

- Jointless executions

- Material 1.4404 / 1.4571 / 1.4435

- Premium - welding seams

- Surfaces up to Ra = 0,4µm or better

- Complete disassembly for treatment by autoclave

- Stator material PTFE

- Capacity 1800 l/h

- Differential pressure 8 bar

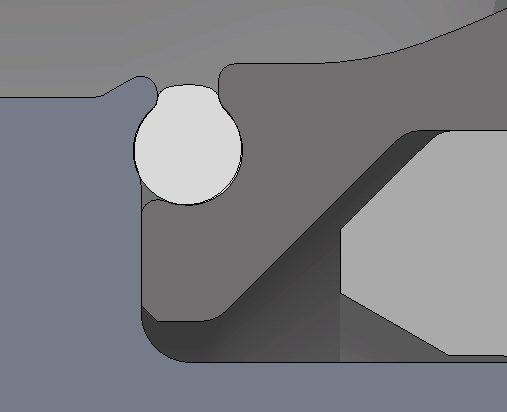

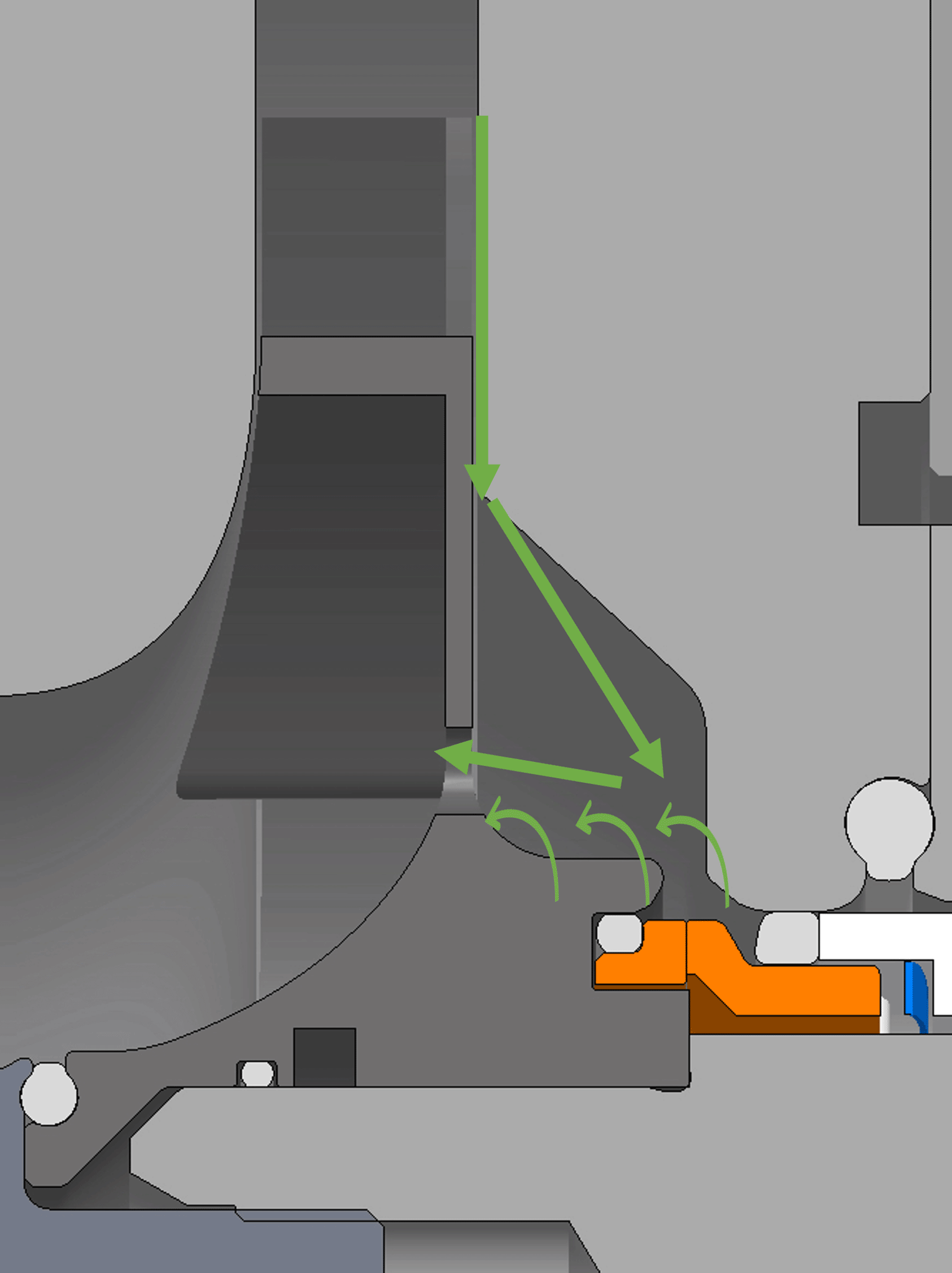

- Scraping system for the hygienic connection and disconnection to fluid bag outlets

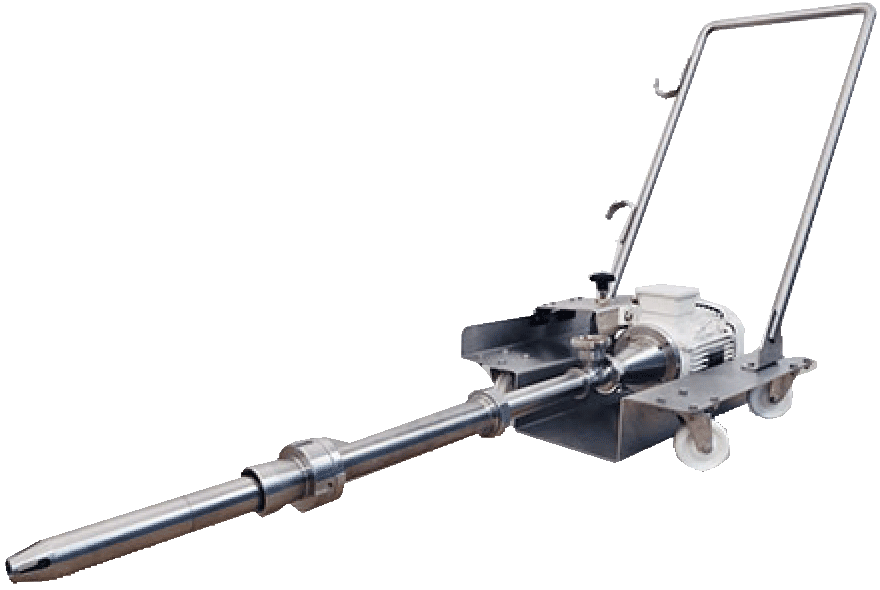

Barrel discharge pumps

- Vertical immersion pump for barrels, open and or with bung as well as for IBC-container

- Jointless execution

- Single and single flushed mechanical seals

- Materials from 1.4301, up to 1.4435

- Surfaces from unmachined up to Ra <= 0,4µm inside and outside <= 0,4µm innen und außen

- Stator material PTFE, Hypalon, NBR black, NBR white, EPDM black, EPDM white

- In the stator incorporated adapter for foot valves

- Easy and flexible handling by means of lifting bows.

Discharge pumps for Fluidbag and barrels

A specialty of ipp Pump Products GmbH is the progressive cavity pump FLB, which as a horizontal immersion pump for fluid bags represents a new standard in the hygienic field of industry. Outstanding hygienic quality as well as extremely easy dismantling are special features of this well thought-out pump concept. The modular design allows the attachment of any rotor / stator size with all material options to one and the same pump for trimming to different standards - from the textile industry to the food industry to the pharmaceutical industry.

Applications

The right pump for high-viscous media

Cosmetics

The effective and at the same time gentle pumping of cosmetics is one of the strengths of ipp Pump Products GmbH. We develop and manufacture pumps that are precisely adapted to your requirements.

Pharmaceuticals

Process pumps for pharmaceuticals and precursors have to meet special requirements. GMP-compliant design is mandatory. ipp rotary lobe pumps are perfectly suited for the gentle transfer of raw materials, ointments, serums, cough syrup, vaccines, homeopathic products and plant extracts.

Chemistry

For transfer, discharge (also from high vacuum), circulation and mixing, dosing, atomization, tank receiving and filling, the ipp rotary lobe pumps can be selected for all individual requirements and operating conditions.

Paints & Lacquers

With the pumps from ipp Pump Products you can gently pump paints, lacquers, varnishes and their individual components such as fillers, binders or color pigments.

Sizes & Technical Data

You have the choice

| Type | Displacement | Maximum pressure | max. rpm | Max. capacitytrom | Pressures | Capacity | Connection width | Nominal Nominal size | Immersion depth |

|---|---|---|---|---|---|---|---|---|---|

| Unit>> | l/rev.] | [bar] | [U/min] | [l/h] | [psi] | [GPM] | [Zoll] | [DN] | [mm] |

| 0080 | 0,0008 | 8 | 1500 | 72 | [114] | [4,5] | [1/2 - 2"] | DN15 – DN50 | 500 - 1200 |

| 0174 | 0,00174 | 8 | 1500 | 158 | [114] | [10,0] | [1/2 - 2"] | DN15 – DN50 | 500 - 1200 |

| 0346 | 0,00346 | 8 | 1500 | 310 | [114] | [19,6] | [1/2 - 2"] | DN15 – DN50 | 500 - 1200 |

| 127 | 0,0127 | 8 | 1500 | 760 | [114] | [47,9] | [1/2 - 2"] | DN15 – DN50 | 500 - 1200 |

| 290 | 0,029 | 8 | 1500 | 1680 | [114] | [106,0] | [1/2 - 2"] | DN15 – DN50 | 500 - 1200 |

| 367 | 0,0367 | 8 | 1500 | 2200 | [114] | [138,8] | [1/2 - 2"] | DN15 – DN50 | 500 - 1200 |

The indicated data may only be evaluated individually. The simultaneous appearance of multiple performance limits may be incorrect. In practice the practicable values may vary, depending on the type of product, respectively on the design of the plant in which the pump is integrated.

Contact person

Ing. (FH) Walerij Stein

Development / Quality Control/ Technical Management

+49 5439 80921-0

O-ring cover housing

O-ring cover housing