Visit us from 02.02. - 05.02.2025

at the international supplier fair for the confectionery and snack industry in Cologne.

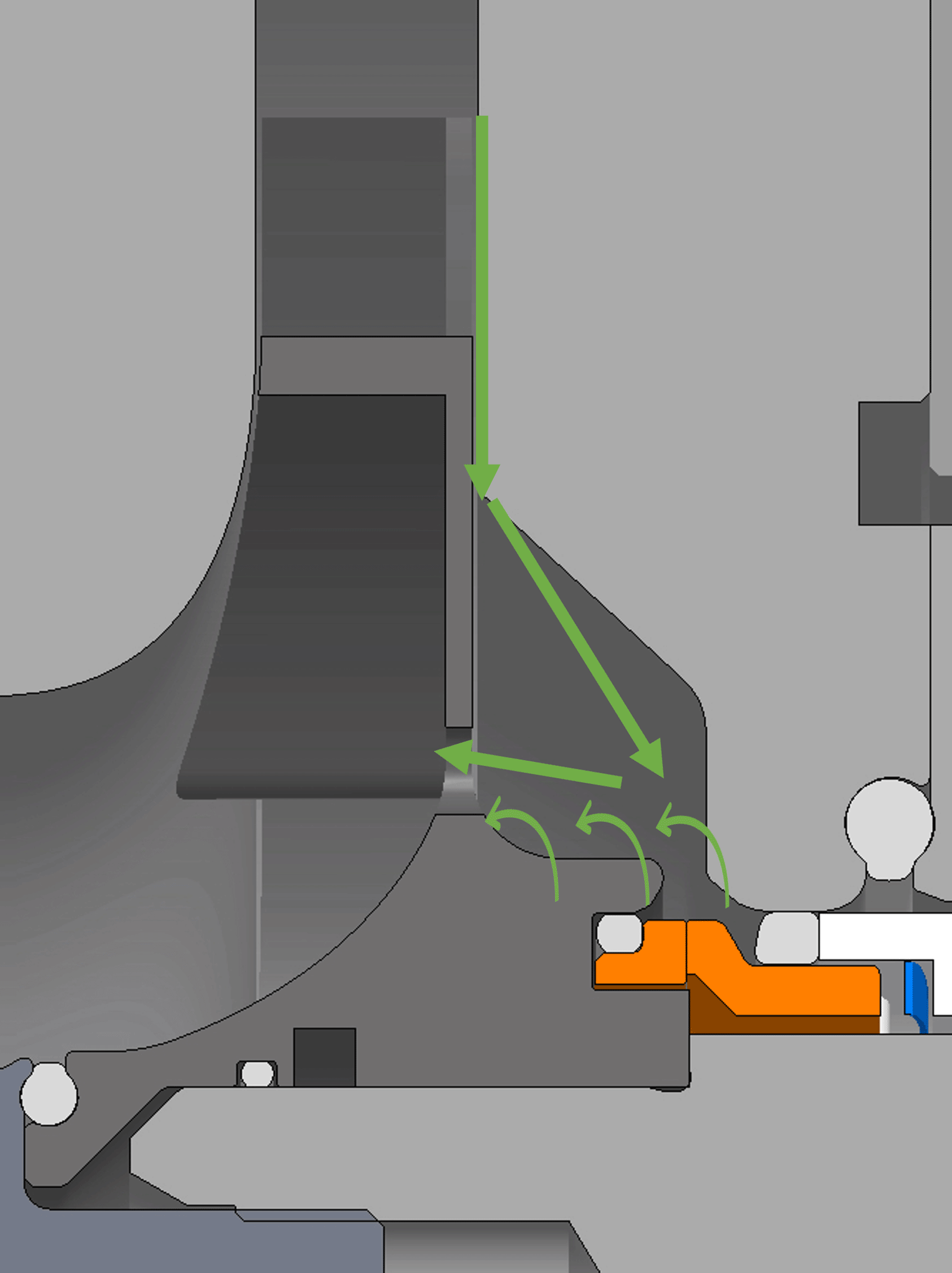

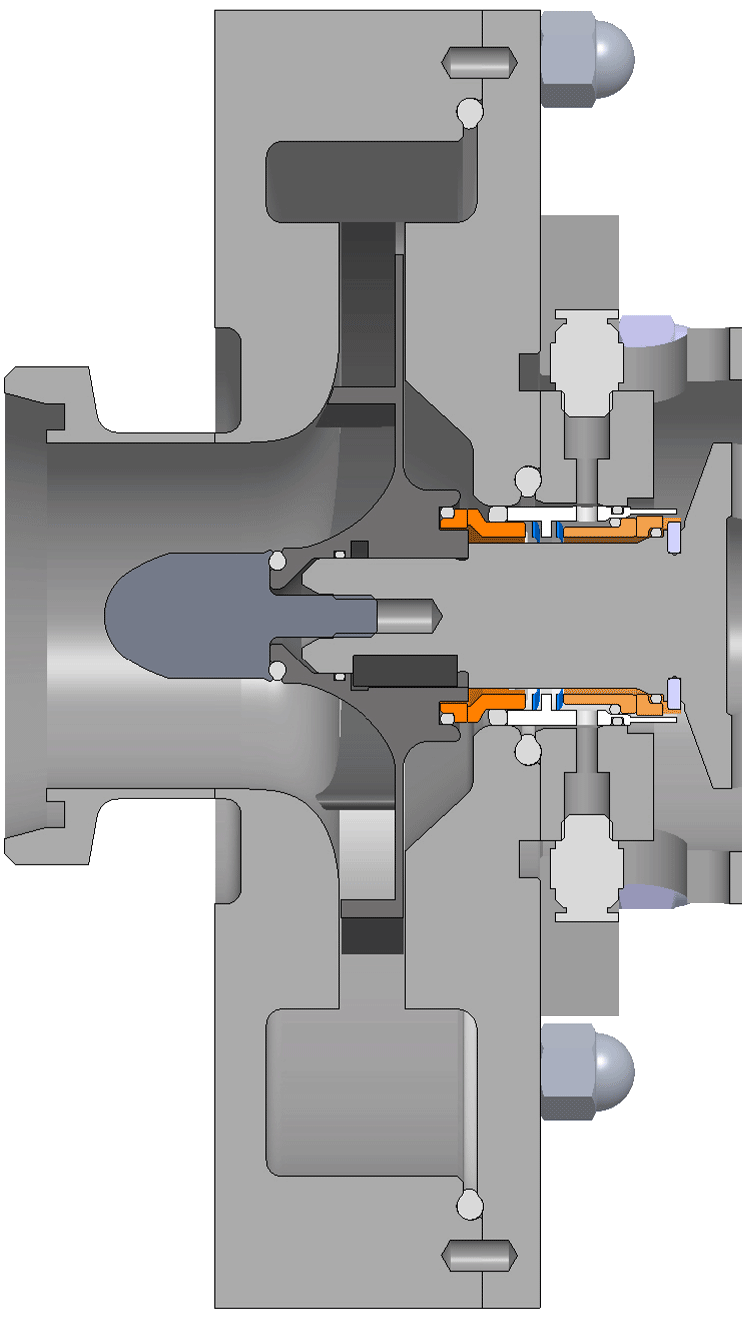

Discover the advantages of the ipp iLobe rotary lobe pump, which was specially developed for the high demands of confectionery production. Experience our expertise and passion for premium pump technology at first hand and watch our powerhouses at work up close.

Look forward to inspiring discussions with our experts and learn more about tailor-made solutions that will revolutionize your production processes.

We look forward to seeing you!

Hall 10.1 | Stand: D-071

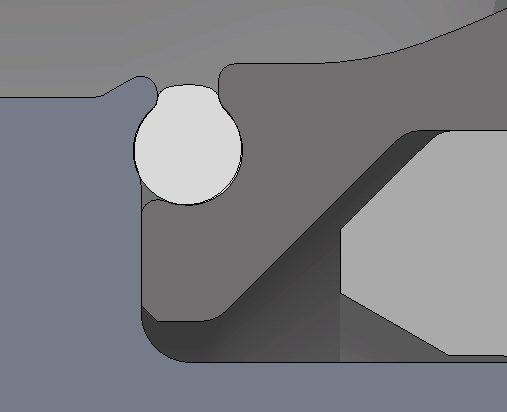

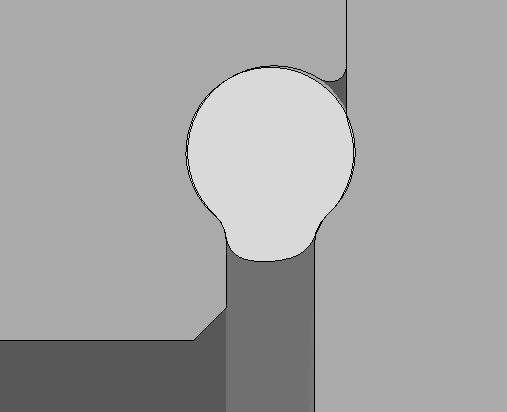

O-ring cover housing

O-ring cover housing