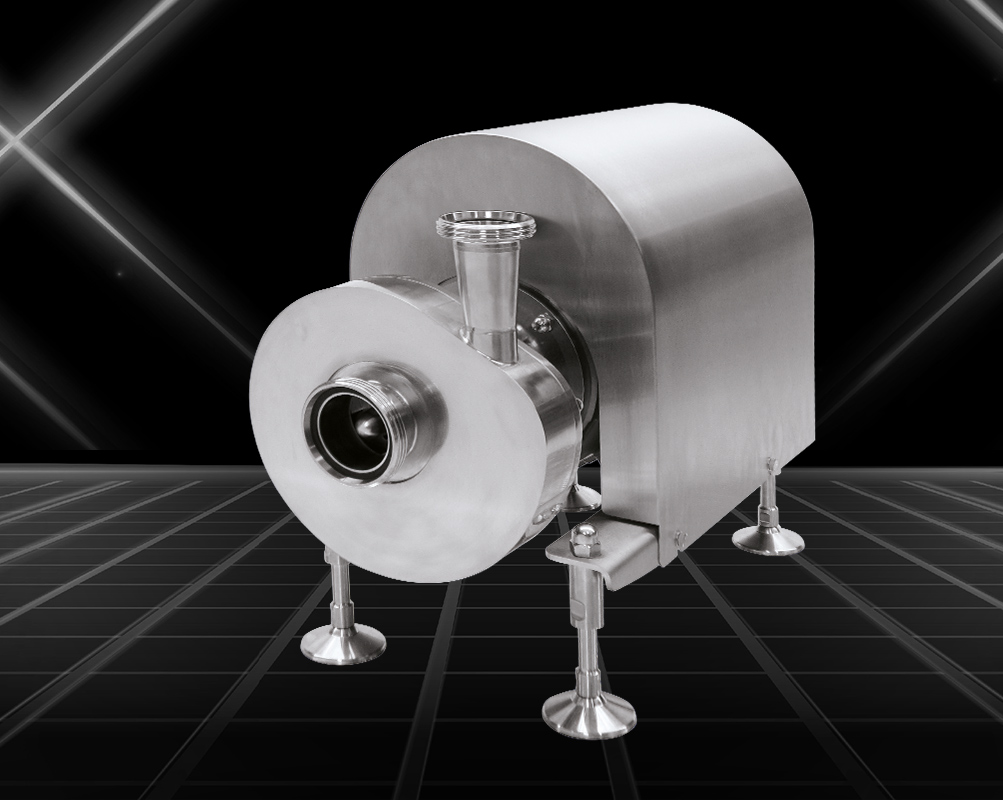

ipp Pump Products GmbH is pleased to announce the expansion of our product range with the Aqueous centrifugal pump. In addition to our proven premium rotary lobe pumps, ipp Premiumlobe and ipp iLobe, we now also offer a first-class solution for pumping low-viscosity media.

The Aqueous centrifugal pump is characterized by its hygienic design, a flow rate of up to 300 m³/h and delivery heads of up to 120 m. With its unrestricted CIP and SIP capability, ATEX certification and suitability for high system pressures, it sets new standards in terms of robustness, flexibility and quality.

Thanks to its modular design and high-quality materials, such as stainless steel 1.4404, the Aqueous centrifugal pump meets the highest hygiene standards and offers a wide range of equipment options for individual customer solutions. Ideal for applications in the beverage, food and pharmaceutical industries, it ensures reliable and long-lasting operation.

Discover the new possibilities with the Aqueous centrifugal pump from ipp Pump Products and benefit from our many years of expertise in pump technology.

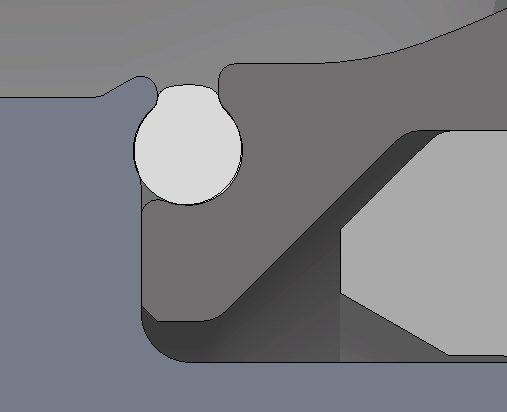

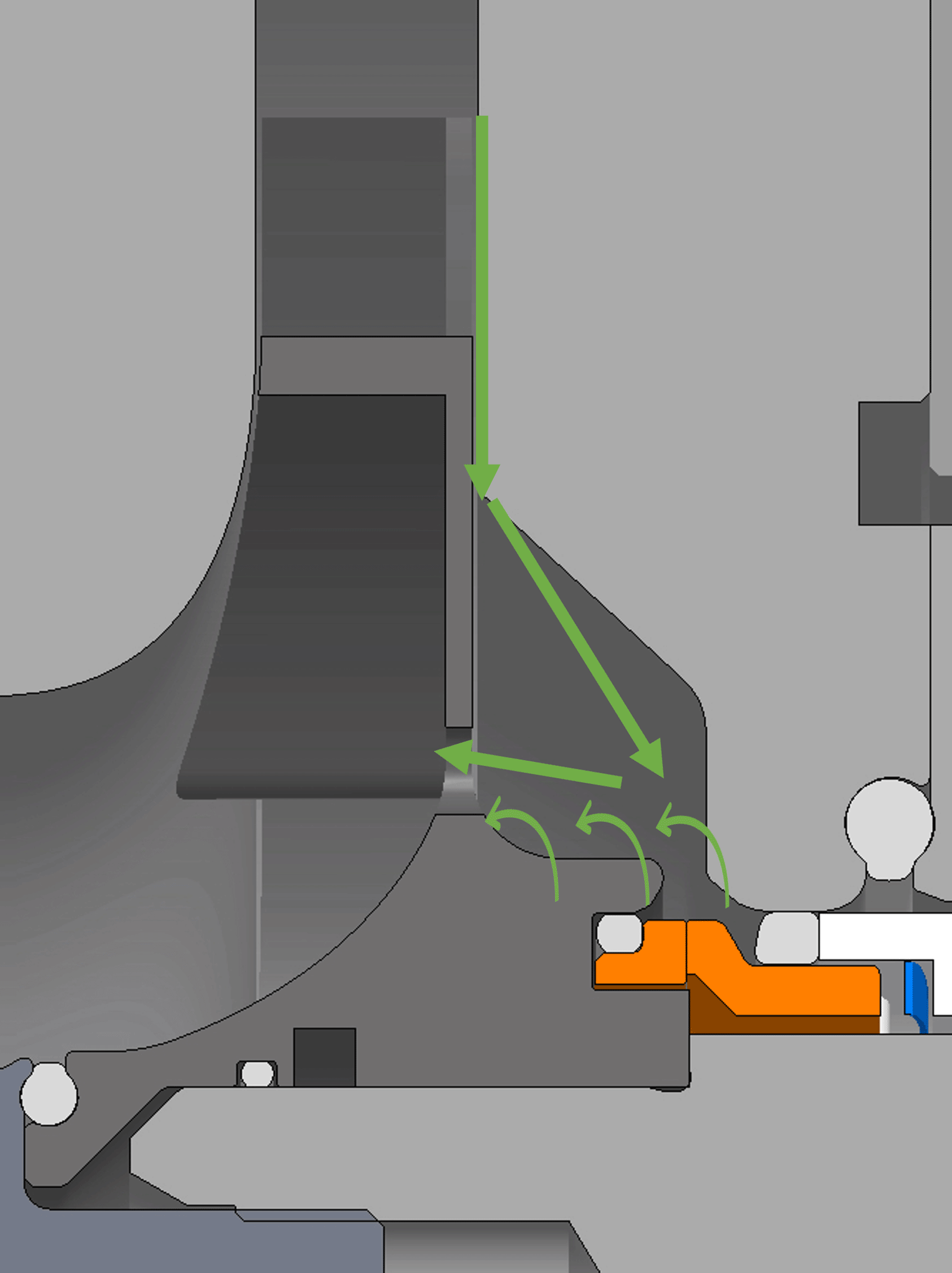

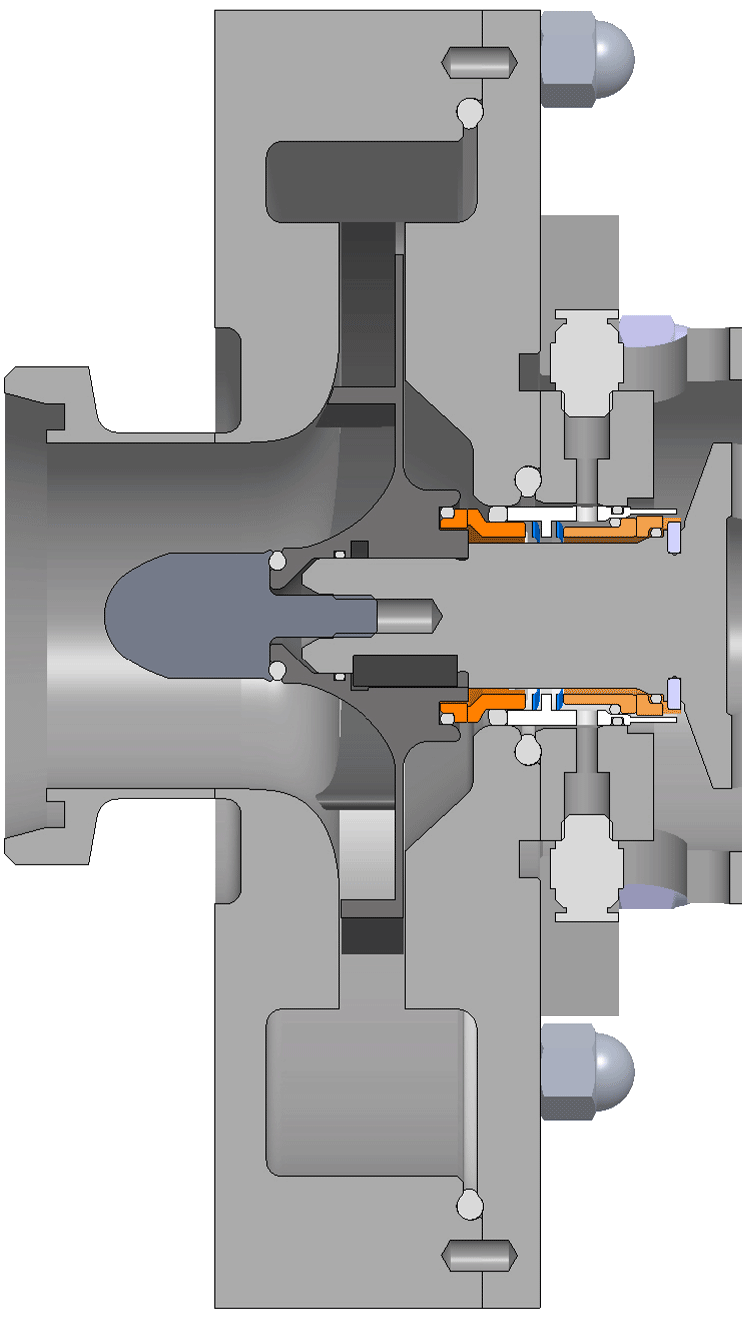

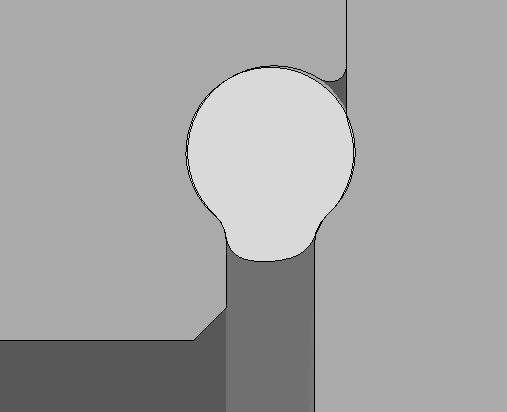

O-ring cover housing

O-ring cover housing