0%

PremiumlobeUltra-Hygienic Design

- Front-loaded Seal Design

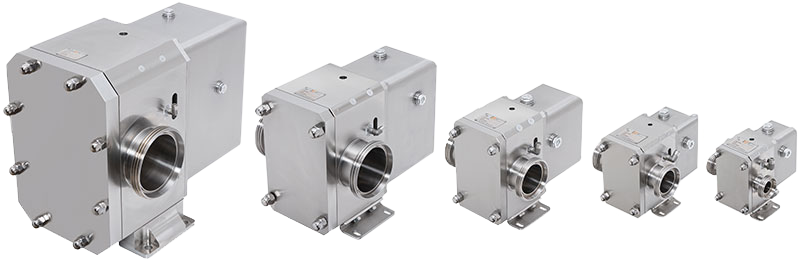

- Capacities upto 163 m3/h

- Differential pressure of 15 up to max. 80 bar

- Wetted components in 1.4404

- optional 1.4435, 1.4539, 1.4462 and Hastelloy

- CIP- and SIP-cleaning procedures are possible without any restriction

- In compliance with EHEDG

- ATEX Zone 1 / 21

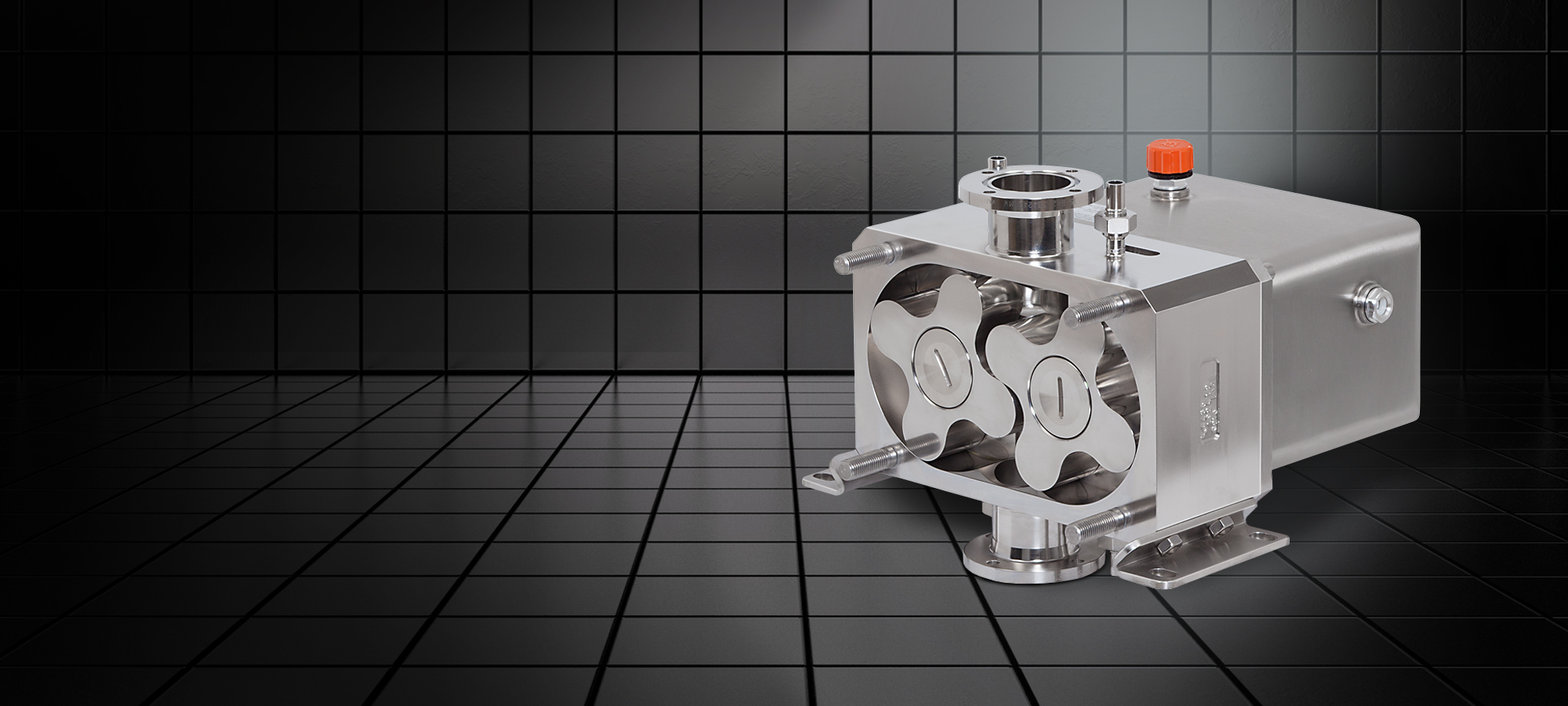

ipp premiumlobe rotary lobe pump

the individual customer solution

The Premiumlobe offers the ideal conditions for use in sophisticated processes. Due to a conclusive concept for hygienic and non-hygienic applications it is a synthesis of highest technical know-how and practical feasibility.

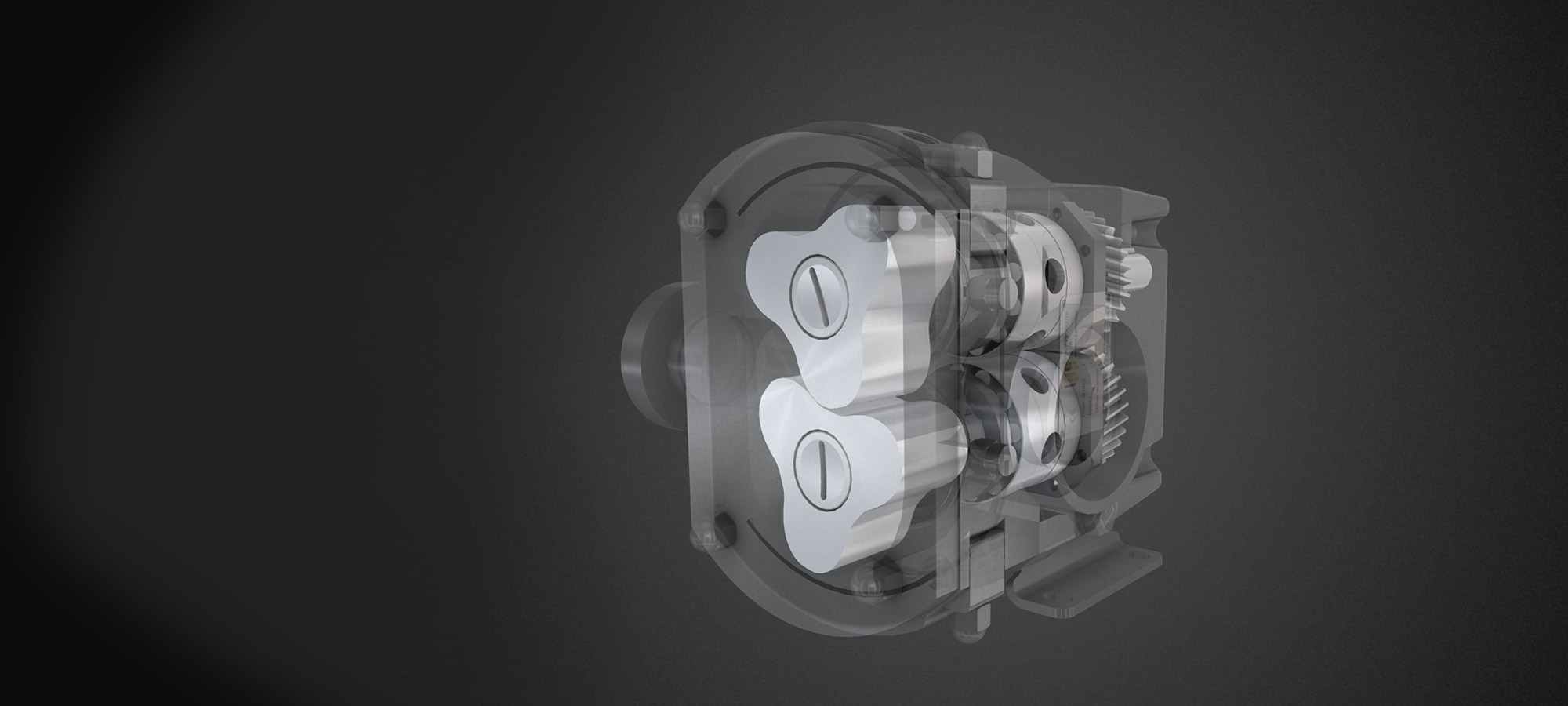

The contactless running of the pump elements in rotary lobe pumps opens up important perspectives: On one hand it is perfect for hygienic applications due to the complete elimination of abrasion and product contamination; on the other hand the pump elements are wear-free with clean liquids.

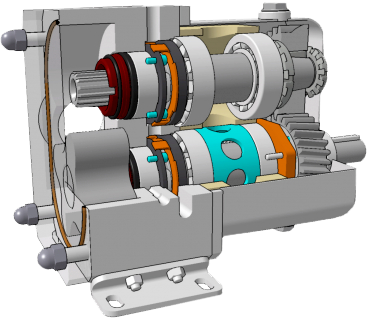

An innovative design of the gearbox and the shaft configuration is part of our mission in order to improve significantly the performance of the PREMIUMLOBE compared to other pumps, mainly conventionally designed: Shafts with an extremely short shaft overhang and large diameters for maximum stiffness; preferably large bearings with high capacity in order to increase service life and reliability and to allow high pressures; selection of material with preferably low coefficient for thermal expansion in order to reduce temperature shock sensibility.

Surfaces and materials

- 1.4404 standard (equal AISI 316L) for wetted metallic material

- 1.4435, 1.4539 and 1.4462 optionally (lowest delta-ferrit contents).

- Raw material always high quality rolled steel. No use of cast iron parts due to danger of porosity

- Special "cold" welding procedures are standard.

- Electro polishing and any surface harshness up to Ra<0,4 µm are available.

Technical concept

The contactless running of the pumping elements of rotary lobe pumps opens up important vistas: On the one hand the perfect suitability for hygienic applications as abrasion and product contamination can be fully eliminated and on the other hand the non-wearing of the conveying elements when pumping clean liquids. These attributes result in minimum life cycle cost. The contactless running of the pumping elements is guaranteed while maintaining the full capacity.

This poses a challenge to the designing of the gearbox. The external bearing of rotary lobe pumps must enable the pump to hold the rotor almost concentric and on the axial level centric in the rotor case in nearly all operation situations.

However, the non-contact of the pumping elements is contradictory to the capacity. The gaps which are essential for the non-contact allow a return-flow of the pumped medium from the pressure side to the inlet site. This return-flow through the gap is called “slip” which becomes noticeable mainly when pumping low-viscous media and cares for a cleaning without residues of the internal components of the rotary lobe pump.

Mechanical aspects

Ensure the contactless running of the pumping elements

- Bending of the shaft due to differential pressure:

The bearing and the shafts of the Premiumlobe-gearbox are designed for a minimum shaft bending which means that all models can be operated with fully contactless pumping elements at thet indicated differential pressures. And that with a high volumetric effect, i.e. with small gaps. Differential pressures up to 40 bar at cold commissioning and up to 80 bar with product can be reached. Corresponding pressure resistant housing parts, as for example connectors are chosen in accordance with the requirements. - Different temperature strains of the single components:

The selection of material for the components and their dimensions guarantee that the PREMIUMLOBE can run without restrictions during the CIP- and SIP-procedure, without risk of blooming at the pump case cover or pump case. - Settlements as well as elastic deformation of the synchronisation gearbox:

Through a new combination of force and form locking the synchronizer gear wheels are safe against settlements and loss of timing. This ensures the perfect functioning of the pump on a long term. The gearbox housings are torsion proof.

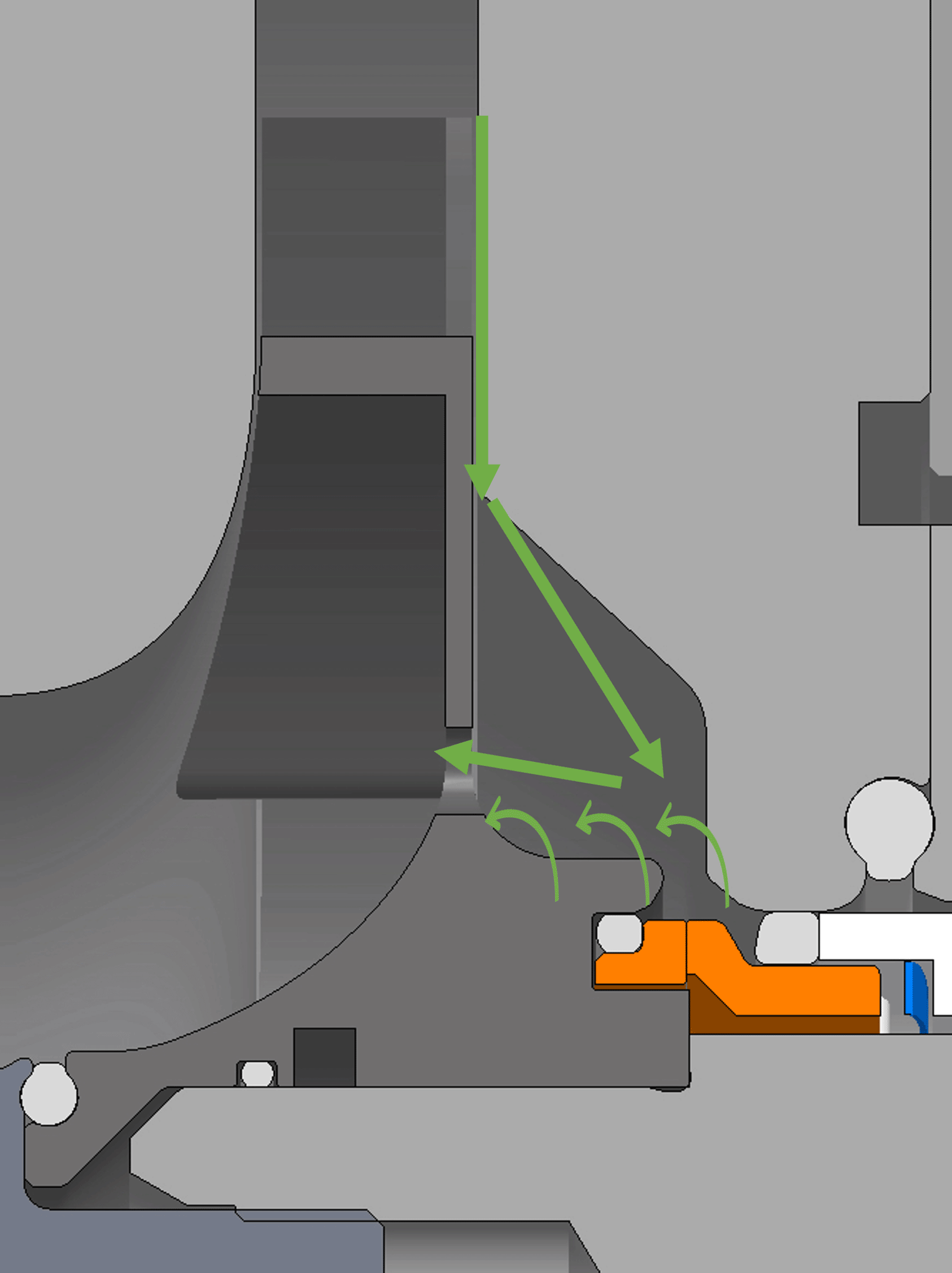

Hygiene is its strength

Free of residues through self cleaning effect (CIP / SIP)

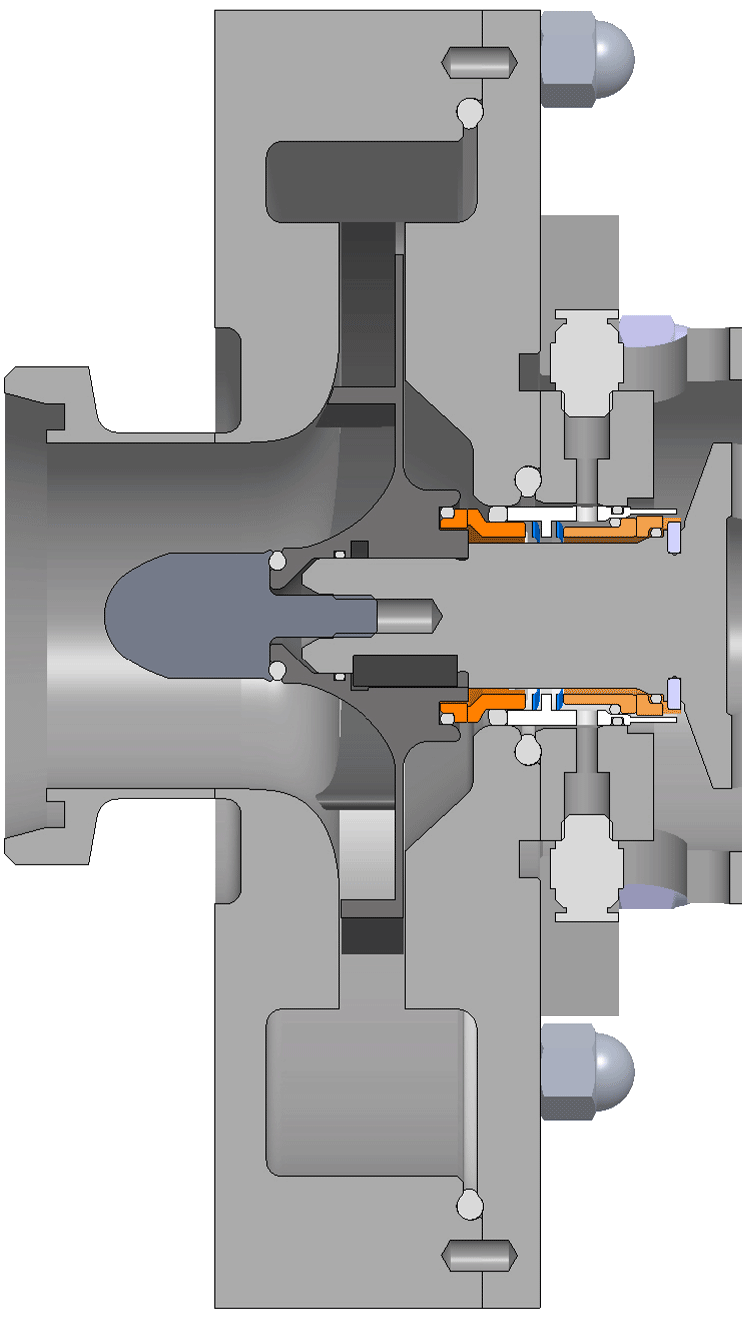

For important operating situations the characteristic slip of the centrifugal and rotary lobe pump is a most welcome side effect as the slip significantly ensures a cleaning function if all pump elements to be cleaned – from the rotor screw to the mechanical seal – are arranged in this flow path. Only the rotary lobe pump offers this effect. FFront loaded mechanical seals (integrated to the rotor) and plane housing covers, both are standard equipment at the Premiumlobe, are imperative conditions for a cleaning without residues (CIP/SIP).

Due to its innovative gearbox design the Premiumlobe can run during the CIP/SIP-procedure, even with high temperature changes.

The active running of the pump during the cleaning process is imperative for an effective CIP procedure as otherwise the slip volume flow which is important for the cleaning effect, wouldn’t arise. A differential pressure of 1…3 bar is enough to achieve the self-cleaning effect of the Premiumlobe.

The flow speed at the critical elements like mechanical seals, rotor screws and o-ring seals often reach upto 20 m/s. However the standard CIP flow speed in the tubes usually reaches 1.8 m/s, max. 3 m/s.

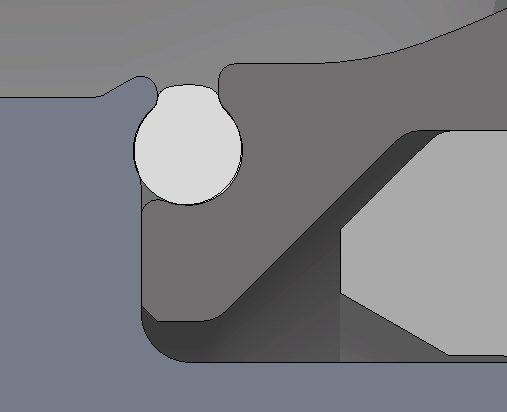

Shaft seals

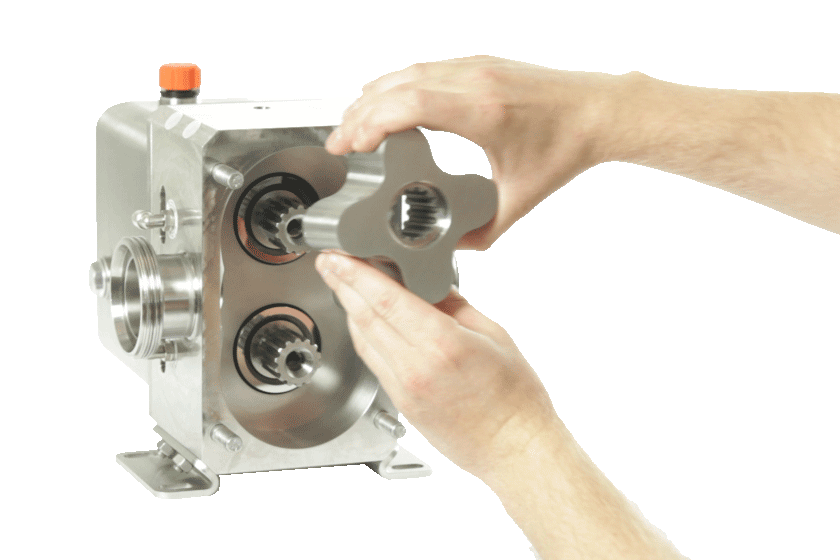

Nonstop-availability due to "Front-Pull-Out"-system.

The modular design of the PREMIUMLOBE series is particularly useful in the sealing area. All the different standard sealing options are accessible from the front as a "front-pull-out principle" and can be interchanged with each other at any time.

The selection of the sealing principle depends on many criteria relating to the plant and the product. Standard materials for mechanical seals are SiC/SiC. The auxiliary gaskets can be made of NBR-FDA, Viton-FDA, or EPDM-FDA.

A choice of O –ring seals and lip rings complete the range of single and double acting mechanical seals.

Applications

The right pump for any application

ipp-rotary lobe pumps can be used for any individual requirements and operation conditions: For transfer, discharge (also from high vacuum), circulation and mixing, dispensing, atomizing, tank discharge and filling. Products like for example sugar, sugar coatings, starch, mashed potatoes, lard, vitamines, glucose syrup, coffee essence, lecithin, clycerine, baby food, salads, salad dressings, spices, sauces, mixings, gelatine, chocolate, dairy products etc. are part of this field of application.

Pumps for every application

Confectionery

Pumping chocolate, marzipan paste, liquid sugar, fudge, jam, marmelade, honey, fruit preparations, sugar mixtures, starch or cocoa butter without affecting their quality and consistence - a challenge which we take on with a lot of experience and innovation power. The sugar contents place very high demands to the shaft seals and the temperature - ipp pumps meet all hygienic requirements and are easily cleanable, i.e. particular suited for chocolate and sweets.

Chocolate & cocoa mass

ipp rotary lobe pumps are also used for processing chocolate. Our variety of rotor profiles guarantees gentle conveying even for products containing solids such as fruit, nuts, brittle or caramel.

Bakery products

You wish to pump dough, fats, fillings, coatings, cream, chocolat or raw products like for example glucose syrup or lecithin: ipp rotary lobe pumps are equal to this sophisticated task under hygienic conditions. Even sticky tough masses are no problem. The pumps are mechanically robust, versatilely trimmable and can be cleaned perfectly.

Dairy products

ipp pumps cover the complex performance range of the food industry and are also suitable for a wide range of pumped media and applications, especially in the dairy processing industry. Rotary lobe pumps are suitable for butter, yogurt and milk.

Cheese products

ipp pumps are particularly suitable in the milk processing industry: For cheese, cheese curd, smear cheese, cheese cream, processed cheese, cream, etc.

Delicatessen

Dressings, sauces mayonnaise, ketchup, tomato paste, mustard, pâtés, whole eggs, egg whites, egg yolks, jams and marmalades (also with whole fruits), honey gentle conveying is a specialty of ipp Pump Products.

Marinades, Breadings & Instant Food

Gently conveying dressings, sauces mayonnaise, ketchup, tomato paste, mustard, pâtés, whole eggs, egg whites, egg yolks, jams and marmalades (also with whole fruits), honey, etc. is a specialty of ipp Pump Products.

Beverages

With the products from ipp Pump Products GmbH you gently pump alcohol, beer, yeast, fruit juice, lemonades as well as mineral water, fruit juice concentrates, liquor, wine, syrup. The rotary lobe pump Premiumlobe as well as the barrel discharge pump FLB are suited for viscous media, the centrifugal pumps for the aqueous media.

Juices & Smoothie

With the high tech products from ipp Pump Products GmbH you can gently pump fruit juices, lemonades as well as fruit juice concentrates and smoothies. The Premiumlobe rotary lobe pump is ideal for viscous media.

Hygiene

The effective and at the same time gentle pumping of hygiene products is one of the strengths of ipp Pump Products GmbH. Shampoo, shower gel, soaps, lotions, disinfection and deodorants place the highest demands on positive displacement pumps.

Cosmetics

The effective and at the same time gentle pumping of cosmetics is one of the strengths of ipp Pump Products GmbH. We develop and manufacture pumps that are precisely adapted to your requirements.

Pharmaceuticals

Process pumps for pharmaceuticals and precursors have to meet special requirements. GMP-compliant design is mandatory. ipp rotary lobe pumps are perfectly suited for the gentle transfer of raw materials, ointments, serums, cough syrup, vaccines, homeopathic products and plant extracts.

Biotechnology

The pumping of vaccines, fermentations, solutions, cell cultures, blood or blood plasma places special demands on a pump in terms of hygiene and product protection and documentation. ipp rotary lobe pumps are perfectly tailored to the requirement profiles of this industry.

Chemistry

For transfer, discharge (also from high vacuum), circulation and mixing, dosing, atomization, tank receiving and filling, the ipp rotary lobe pumps can be selected for all individual requirements and operating conditions.

Paints & Lacquers

With the pumps from ipp Pump Products you can gently pump paints, lacquers, varnishes and their individual components such as fillers, binders or color pigments.

Sizes & Technical Data

| Type | Displace-ment | Displace-ment | max. Differenz- druck | max. Differenz- druck | max. rpm | Anschluss- weite | Anschluss- weite | Weight | Weight | TCIP | TSIP | QCIP @2bar;1,8m/s |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit>> | [l/rev.] | [USgal/rev.] | [bar] | [psi] | [U/min] | [DN] | [Zoll] | [kg.] | [lbs] | [85...90°C] | [120...130°C] | [m3/h] |

| L55sxx | 0,010 | 0,003 | 15 | 218 | 1400 | DN15 | 1/2 | 10,5 | 23 | ja | ja | -- |

| L55sx | 0,030 | 0,008 | 15 | 218 | 1400 | DN15 | 1/2 | 10 | 22 | ja | ja | 1,4 |

| L55s | 0,039 | 0,010 | 15 | 218 | 1400 | DN15 | 1/2 | 10,5 | 23 | ja | ja | 2,1 |

| L55i | 0,056 | 0,015 | 15 | 218 | 1400 | DN25 | 1 | 11 | 24 | ja | ja | 3,1 |

| L55li | 0,076 | 0,020 | 15 | 218 | 1400 | DN40 | 1 1/2 | 11,5 | 25 | ja | ja | 4,4 |

| L55l | 0,094 | 0,025 | 9 | 131 | 1400 | DN40 | 1 1/2 | 12 | 26 | ja | ja | 5,9 |

| L63i | 0,120 | 0,032 | 15 | 218 | 1400 | DN40 | 1 1/2 | 17 | 37 | ja | ja | 7,0 |

| L63l | 0,180 | 0,047 | 15 | 218 | 1400 | DN50 | 2 | 19 | 42 | ja | ja | 10,5 |

| L85sxx | 0,100 | 0,026 | 80 | 1160 | 1100 | DN15 | 1/2 | 38 | 84 | ja | ja | 3,8 |

| L85sx | 0,169 | 0,045 | 30 | 435 | 1100 | DN32 | 1 1/4 | 33 | 73 | ja | ja | 7,5 |

| L85s | 0,210 | 0,055 | 20 | 290 | 1100 | DN40 | 1 1/2 | 35 | 77 | ja | ja | 10,5 |

| L85i | 0,280 | 0,074 | 15 | 218 | 1100 | DN50 | 2 | 38 | 84 | ja | ja | 14,4 |

| L85l | 0,350 | 0,092 | 15 | 218 | 1100 | DN65 | 2 1/2 | 40 | 88 | ja | ja | 18,0 |

| L115sxx | 0,300 | 0,079 | 80 | 1160 | 950 | DN25 | 1 | 100 | 220 | ja | ja | 11,3 |

| L115sx | 0,400 | 0,106 | 30 | 435 | 950 | DN40 | 1 1/2 | 90 | 198 | ja | ja | 15,8 |

| L115s | 0,550 | 0,145 | 20 | 290 | 950 | DN50 | 2 | 95 | 209 | ja | ja | 24,3 |

| L115si | 0,750 | 0,198 | 20 | 290 | 950 | DN65 | 2 1/2 | 98 | 216 | ja | ja | 31,5 |

| L115i | 0,950 | 0,251 | 15 | 218 | 950 | DN80 | 3 | 101 | 223 | ja | ja | 43,0 |

| L115l | 1,230 | 0,325 | 15 | 218 | 950 | DN100 | 4 | 110 | 243 | ja | ja | 56,7 |

| L130sx | 1,230 | 0,325 | 40 | 580 | 850 | DN65 | 2 1/2 | 170 | 375 | ja | ja | 24,7 |

| L130s | 1,600 | 0,422 | 22 | 319 | 850 | DN80 | 3 | 181 | 399 | ja | ja | 37,1 |

| L130i | 1,970 | 0,520 | 15 | 218 | 850 | DN100 | 4 | 192 | 423 | ja | ja | 56,5 |

| L130l | 2,340 | 0,612 | 9 | 131 | 850 | DN100 | 4 | 202 | 445 | ja | ja | 56,5 |

| L160sxx | 1,030 | 0,272 | 80 | 1160 | 800 | DN32 | 1 1/4 | 245 | 540 | ja | ja | 40,0 |

| L160sx | 1,290 | 0,340 | 50 | 725 | 800 | DN50 | 2 | 255 | 562 | ja | ja | 50,8 |

| L160s | 1,600 | 0,422 | 30 | 435 | 800 | DN80 | 3 | 245 | 540 | ja | ja | 65,2 |

| L160i | 2,400 | 0,633 | 20 | 290 | 800 | DN100 | 4 | 270 | 595 | ja | ja | 108,0 |

| L160l | 3,410 | 0,900 | 15 | 218 | 800 | DN150 | 6 | 320 | 705 | ja | ja | 148,4 |

The indicated data may only be evaluated individually. The simultaneous appearance of multiple performance limits may be incorrect. In practice the practicable values may vary, depending on the type of product, respectively on the design of the plant in which the pump is integrated.

The operation limits are variable. In particular Δ p max can be higher at certain applications. The robust execution of the gearbox and the shafts allow maximum pressures up to 80 bar. For a precise dimensioning a detailed examination of the operating conditions is necessary.

Contact person

Ing. (FH) Walerij Stein

Development / Quality Control/ Technical Management

+49 5439 80921-0

Downloads

Here you can download further information about the ipp Premiumlobe:

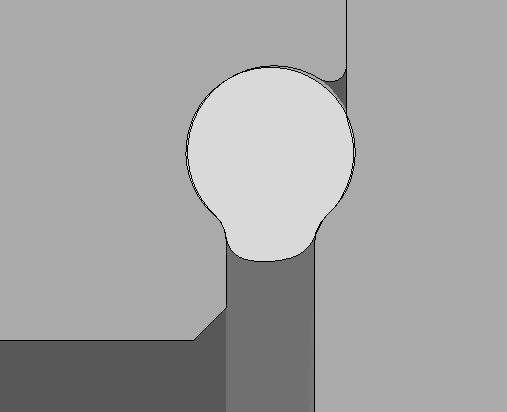

O-ring cover housing

O-ring cover housing