Downloads

All downloads in the overview

Downloads for the Premiumlobe

Here you can download further information about the ipp Premiumlobe:

Downloads for the iLobe

Here you can download further information about the ipp iLobe:

Downloads for centrifugal pumps Aqueous

Here you can download further information about the ipp Aqueous:

Further download offers

Here you can download further information:

If you have specific questions, you can contact the relevant contact person directly.

Benjamin Klein

On site assistance

+49 5439 80921-0

B.Sc. Michael Krone

Technical support

+49 5439 80921-0

mkrone@pump-products.de

Christiane Schimpfky

Shipping & Distribution

+49 5439 80921-0

cschimpfky@pump-products.de

Call now directly

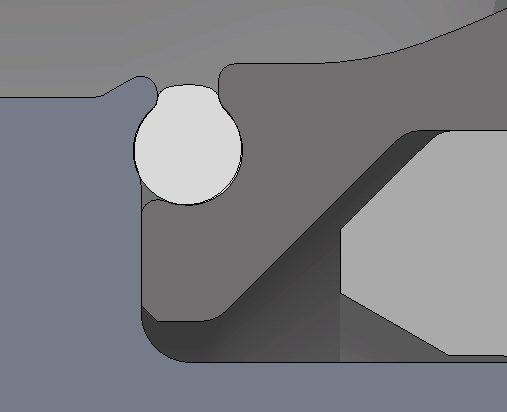

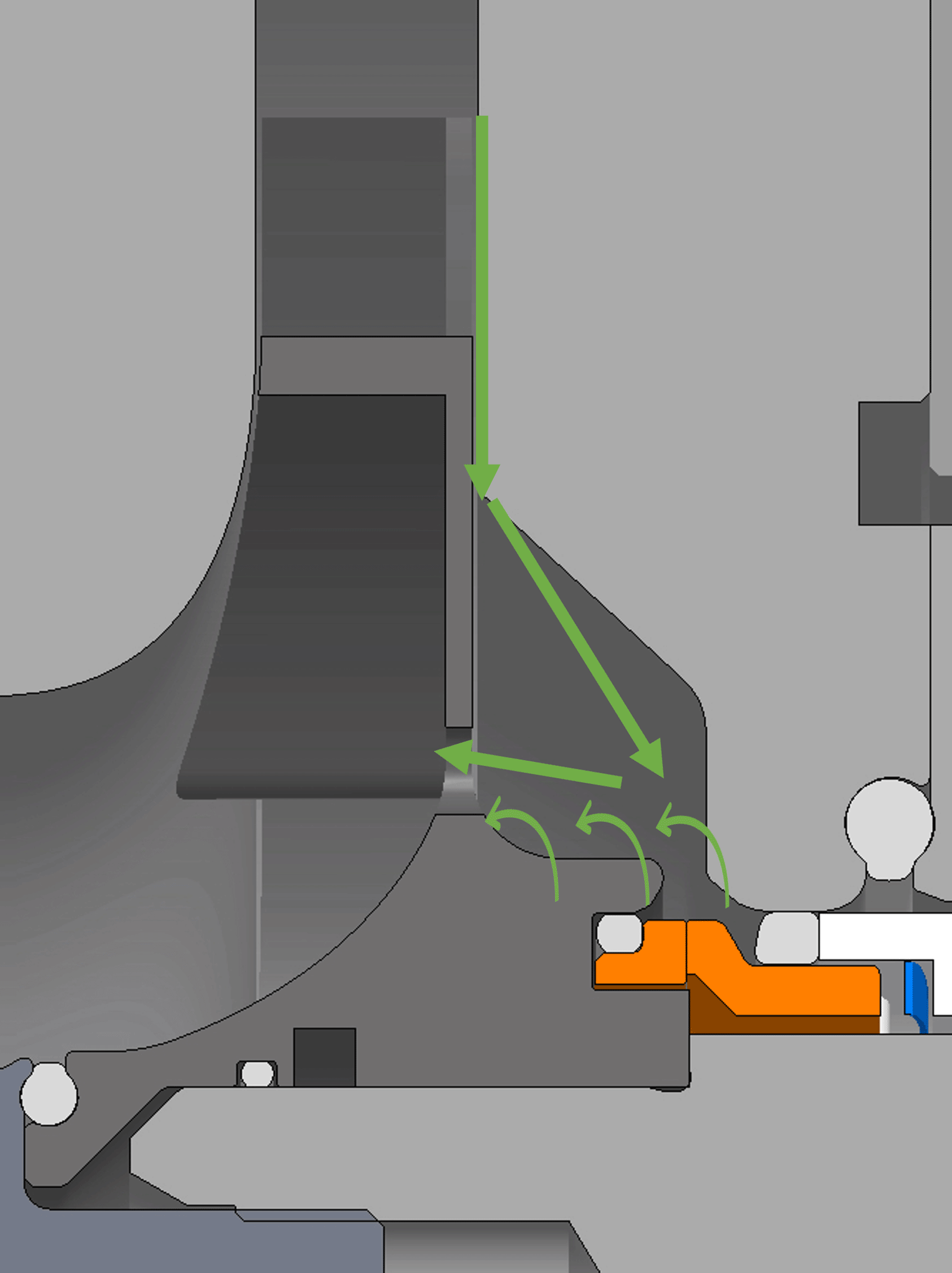

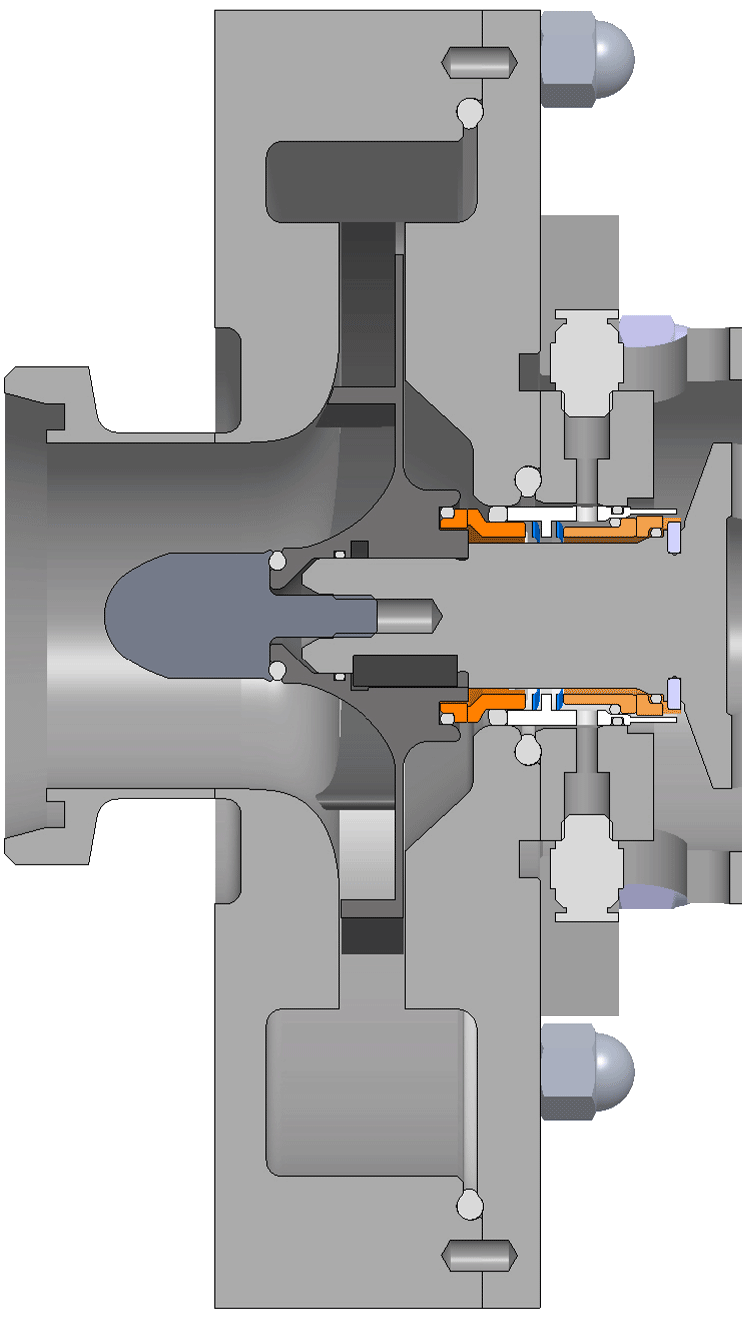

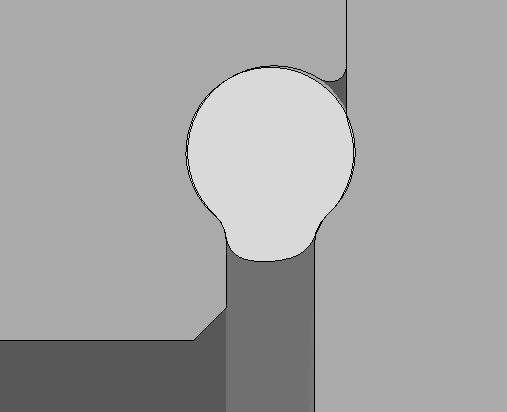

O-ring cover housing

O-ring cover housing