Pumpen für Wein

Mit den Pumpen von ipp Pump Products pumpen Sie schonend Ihr Premiumprodukte Wein. Die ipp Kreiselpumpe oder die Drehkolbenpumpen sichern die Güte während der Verarbeitungsprozesse.

Textliche Alternative:

Für die Weinherstellung sind ipp Drehkolbenpumpen und die Aqueous Kreiselpumpe perfekt geeignet. Drehkolbenpumpen gewährleisten eine sanfte Förderung von Traubenmaische, Most und Wein, um die empfindlichen Aromen zu bewahren. Die Kreiselpumpe besticht durch hygienisches Design, rückstandsfreie Reinigung (CIP/SIP) und hohe Leistungsfähigkeit, wodurch sie optimal für Transport, Umwälzung und Abfüllung von Wein ist.

Requirements

- Exact configuration and perfect functioning

- Neutral product treatment with high quality products

- Performance and suction capability

- Prozess reliability

- Serviceability

- Simplicity

- Versatile use

- Low life cycle cost

- Hygiene - Cleaning without residues and free from dead spaces

- Compliance with applicable directives and laws

- Exzellent price-performance ratio

- Modularer Aufbau für flexible Anpassungen

- Robustheit und Langlebigkeit durch hochwertige Materialien

- ATEX-Zertifizierung für explosionsgefährdete Umgebungen

Performance fulfillment

- Advantage due to know-how and experience

- Preservation of all admixtures

- Various options– restyled rotor profiles

- Selection of material

- Individual specification according to customers' requirements

- Highest process safety due to performance reserve

- Super-hygienic execution, free of dead zones

- Product pump = CIP-pump

- Low maintenance requirements with high performance and permanent use

- Easy maintenance and serviceability

- Compliant with directive CE 1935/2004

- Hohe Maßhaltigkeit und geringe Unwuchten

- Rückstandsfreiheit durch Selbstreinigung (CIP/SIP)

- Optionaler Wärmetauscher zur Temperaturkontrolle

Contact person

B.Sc. Matthias Pohlkamp

Applications expert/ Sales

+49 5439 80921-0

mpohlkamp@pump-products.de

Contact person

Thomas Genschel

Applications expert/ Sales

+49 5439 80921-0

tgenschel@pump-products.de

Contact person

B.Sc. Michael Krone

Technical support

+49 5439 80921-0

mkrone@pump-products.de

Call now directly

The right pump for your application

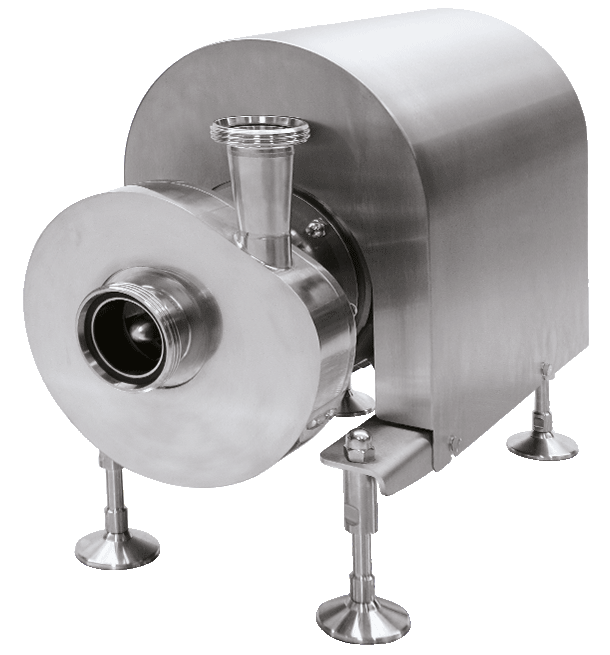

Aqueous centrifugal pump

Premium centrifugal pumps for low-viscosity media

Advantages:

- Excellent for high system pressures

- Modular design of pump & mechanical seal for non-stop availability

Application fields:

- Oils

- Dairy products

- Juices & Beverages

- Wine

- Beer

- Pharmaceuticals

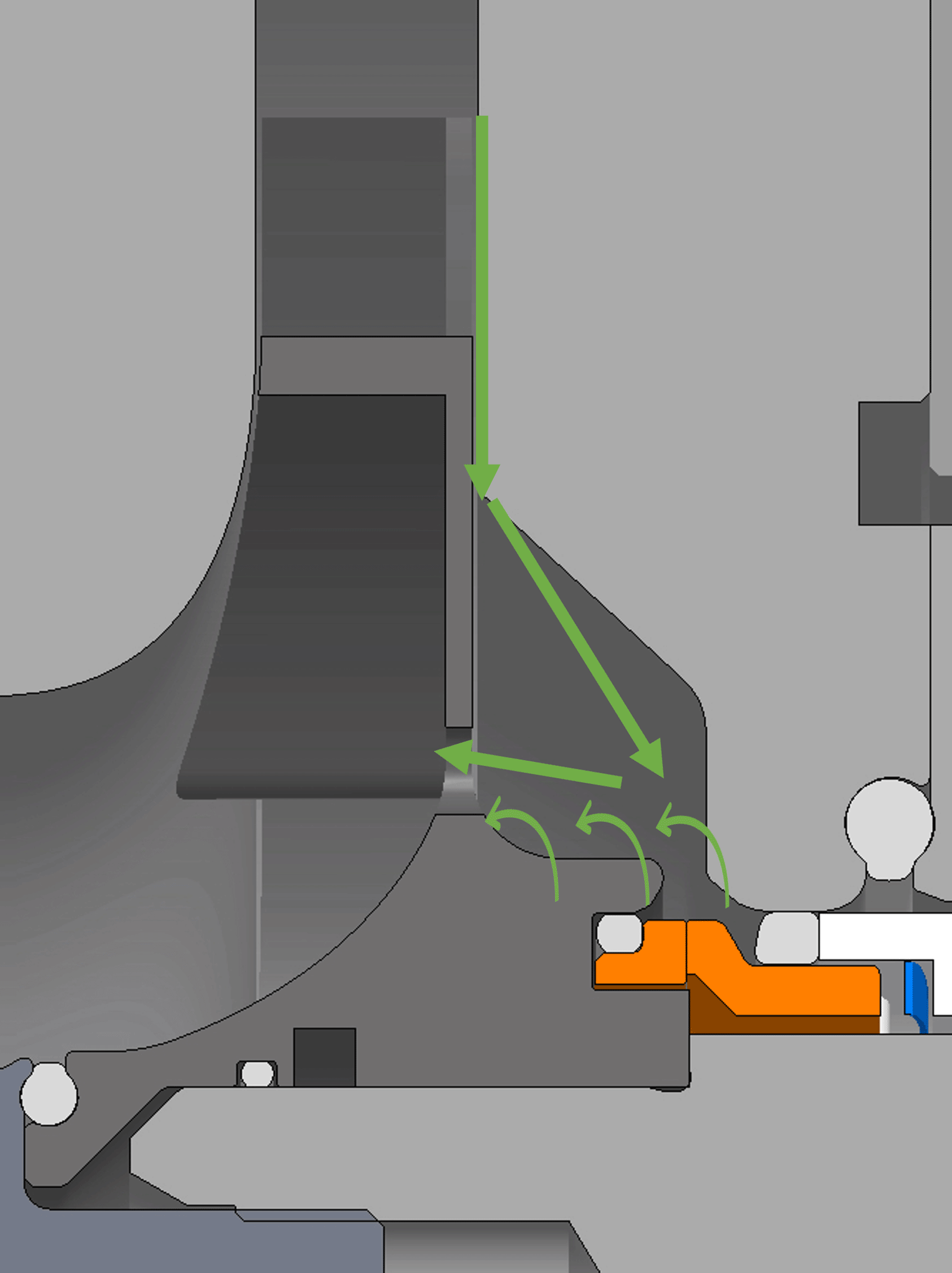

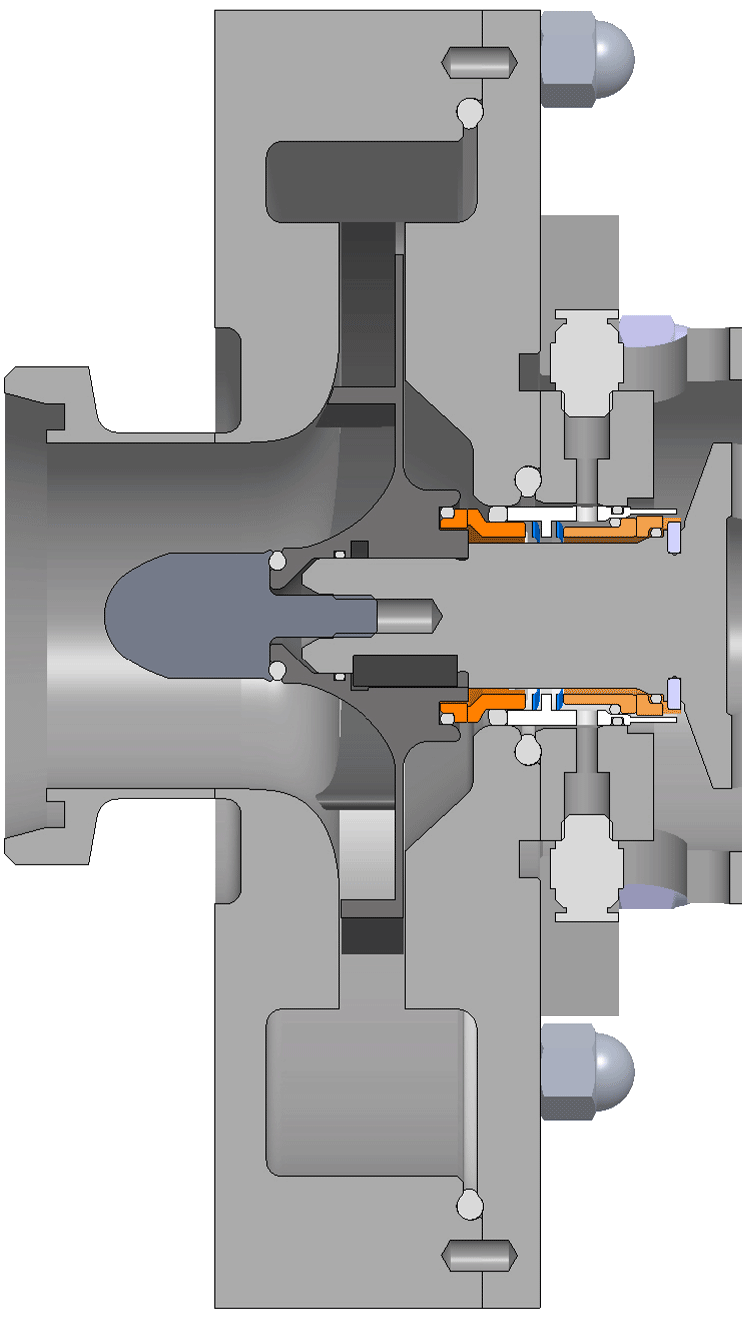

Premiumlobe - High Tech for Hygiene

Advantages:

- Completely made of stainless steel

- Differential pressures up to 80 bar

- Highest functionabilty

Application fields:

- Dairy products

- Delicatessen

- Biotechnology

- Chemistry

- Pharmaceuticals

- Beverages

- Cosmetics

Pumps for every application

Confectionery

Pumping chocolate, marzipan paste, liquid sugar, fudge, jam, marmelade, honey, fruit preparations, sugar mixtures, starch or cocoa butter without affecting their quality and consistence - a challenge which we take on with a lot of experience and innovation power. The sugar contents place very high demands to the shaft seals and the temperature - ipp pumps meet all hygienic requirements and are easily cleanable, i.e. particular suited for chocolate and sweets.

Chocolate & cocoa mass

ipp rotary lobe pumps are also used for processing chocolate. Our variety of rotor profiles guarantees gentle conveying even for products containing solids such as fruit, nuts, brittle or caramel.

Bakery products

You wish to pump dough, fats, fillings, coatings, cream, chocolat or raw products like for example glucose syrup or lecithin: ipp rotary lobe pumps are equal to this sophisticated task under hygienic conditions. Even sticky tough masses are no problem. The pumps are mechanically robust, versatilely trimmable and can be cleaned perfectly.

Dairy products

ipp pumps cover the complex performance range of the food industry and are also suitable for a wide range of pumped media and applications, especially in the dairy processing industry. Rotary lobe pumps are suitable for butter, yogurt and milk.

Cheese products

ipp pumps are particularly suitable in the milk processing industry: For cheese, cheese curd, smear cheese, cheese cream, processed cheese, cream, etc.

Delicatessen

Dressings, sauces mayonnaise, ketchup, tomato paste, mustard, pâtés, whole eggs, egg whites, egg yolks, jams and marmalades (also with whole fruits), honey gentle conveying is a specialty of ipp Pump Products.

Marinades, Breadings & Instant Food

Gently conveying dressings, sauces mayonnaise, ketchup, tomato paste, mustard, pâtés, whole eggs, egg whites, egg yolks, jams and marmalades (also with whole fruits), honey, etc. is a specialty of ipp Pump Products.

Beverages

With the products from ipp Pump Products GmbH you gently pump alcohol, beer, yeast, fruit juice, lemonades as well as mineral water, fruit juice concentrates, liquor, wine, syrup. The rotary lobe pump Premiumlobe as well as the barrel discharge pump FLB are suited for viscous media, the centrifugal pumps for the aqueous media.

Juices & Smoothie

With the high tech products from ipp Pump Products GmbH you can gently pump fruit juices, lemonades as well as fruit juice concentrates and smoothies. The Premiumlobe rotary lobe pump is ideal for viscous media.

Hygiene

The effective and at the same time gentle pumping of hygiene products is one of the strengths of ipp Pump Products GmbH. Shampoo, shower gel, soaps, lotions, disinfection and deodorants place the highest demands on positive displacement pumps.

Cosmetics

The effective and at the same time gentle pumping of cosmetics is one of the strengths of ipp Pump Products GmbH. We develop and manufacture pumps that are precisely adapted to your requirements.

Pharmaceuticals

Process pumps for pharmaceuticals and precursors have to meet special requirements. GMP-compliant design is mandatory. ipp rotary lobe pumps are perfectly suited for the gentle transfer of raw materials, ointments, serums, cough syrup, vaccines, homeopathic products and plant extracts.

Biotechnology

The pumping of vaccines, fermentations, solutions, cell cultures, blood or blood plasma places special demands on a pump in terms of hygiene and product protection and documentation. ipp rotary lobe pumps are perfectly tailored to the requirement profiles of this industry.

Chemistry

For transfer, discharge (also from high vacuum), circulation and mixing, dosing, atomization, tank receiving and filling, the ipp rotary lobe pumps can be selected for all individual requirements and operating conditions.

Paints & Lacquers

With the pumps from ipp Pump Products you can gently pump paints, lacquers, varnishes and their individual components such as fillers, binders or color pigments.

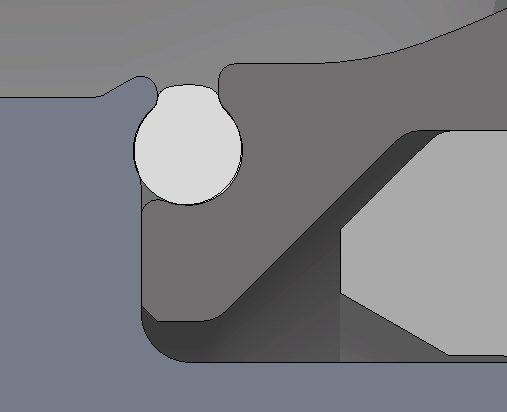

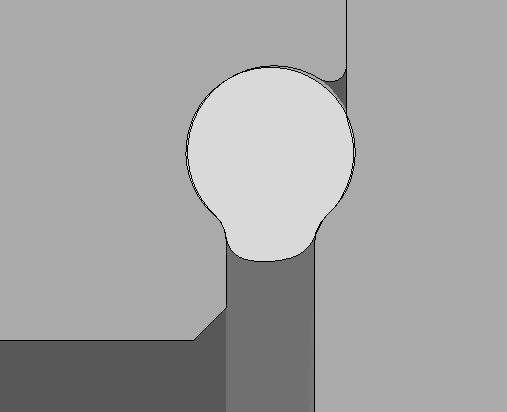

O-ring cover housing

O-ring cover housing