Premiumlobe

iLobe

Progressing

cavity pump

cavity pump

Discharge pumps for Fluidbag & barrels

Aqueous

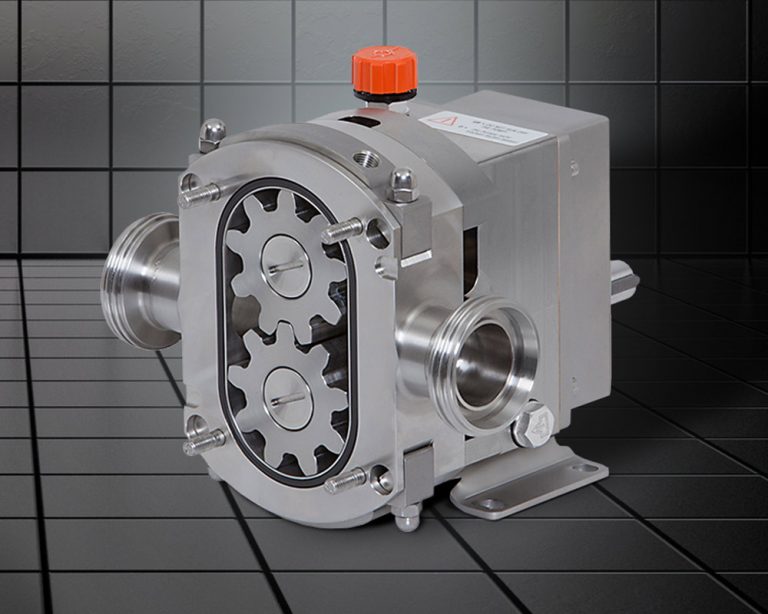

Specialized in rotary lobe pumps

ipp Pump Products GmbH are convinced that for processes with sanitary application, the rotary lobe pump is the best solution from all pumping principles. Due to its contactless running any product contamination through abrasion is avoided. Furthermore being a slow runner it offers the smoothest product handling - in case of increase of speed - the most effective CIP cleanability of the pump or pump and installation. Continue...

PremiumlobeUltra-Hygienic Design

The individual customer solution

- Technical conceptOur pumps open up new vistas

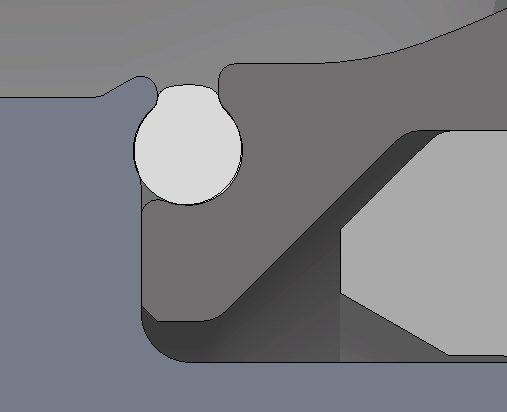

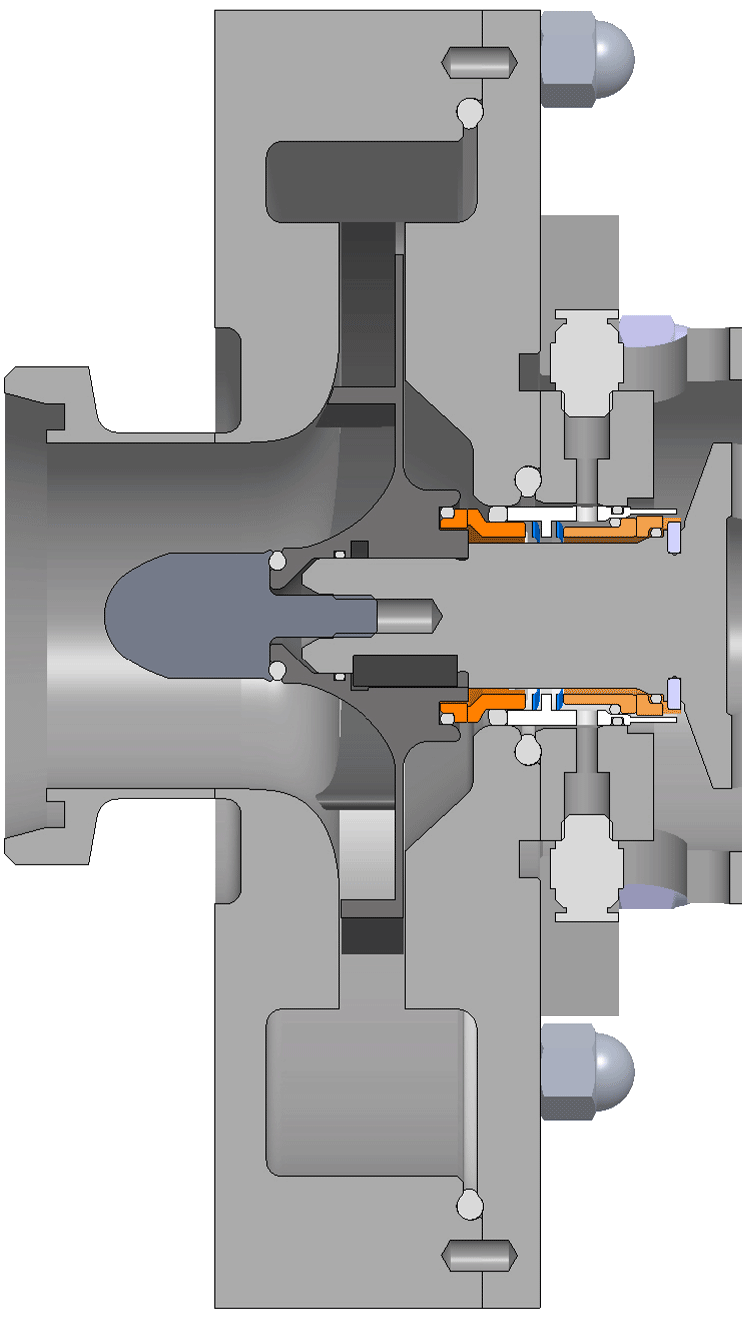

- Mechanical aspectsEnsure the contactless running of the pumping elements

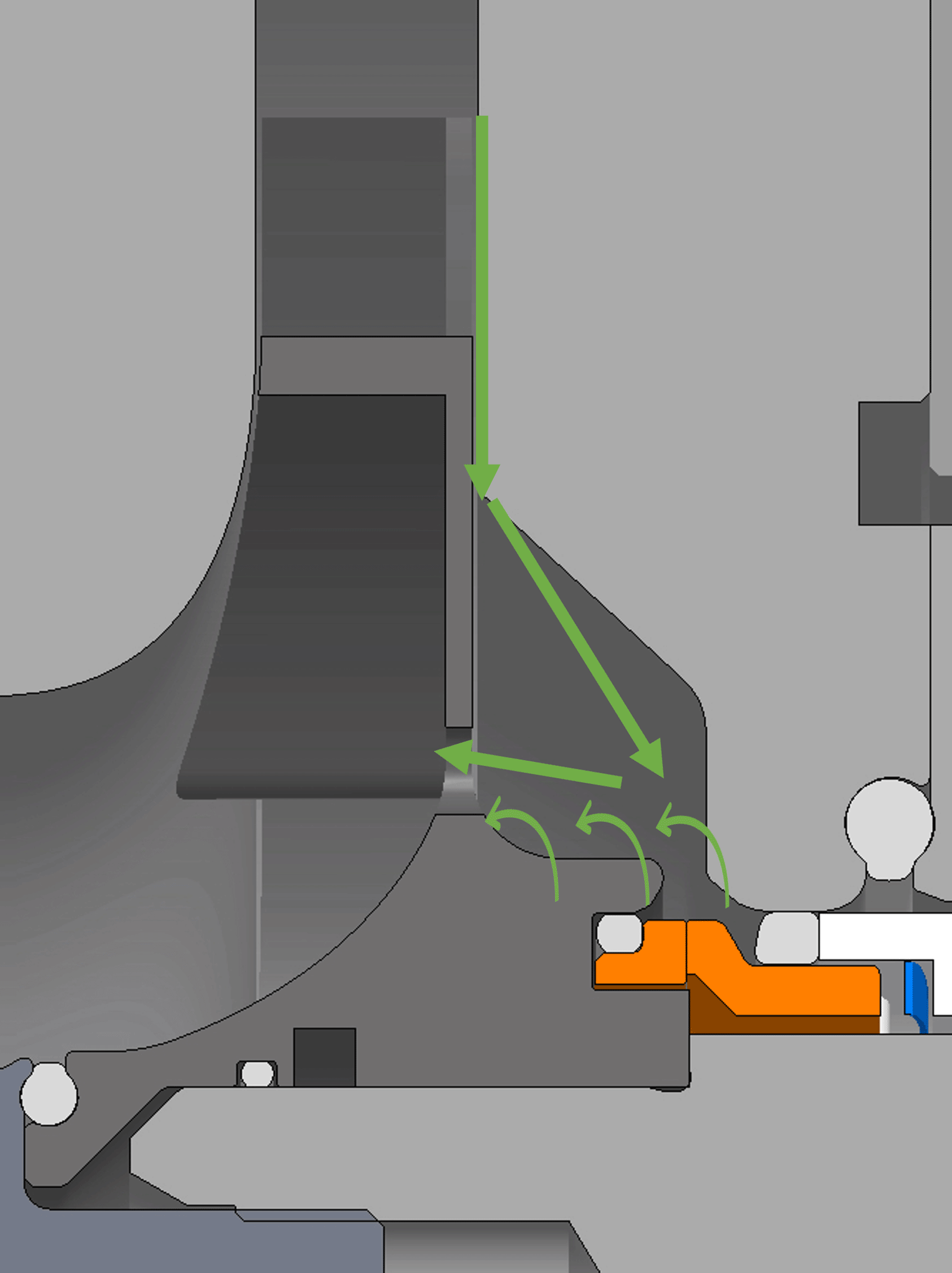

- Hygiene is its strengthFree of residues through self cleaning (CIP / SIP)

- Shaft sealsServiceability

- ApplicationsThe right pump for any application

The specialist for chocolate and sweets

Small Premium Edition

- Technical conceptOur pumps open up new vistas

- Mechanical aspectsEnsure the contactless running of the pumping elements

- Hygiene is its strengthFree of residues through self cleaning (CIP / SIP)

- Shaft sealsServiceability

- ApplicationsThe right pump for any application

Progressing cavity pumps

- Discharge pumps for Fluidbag and barrels

- Fluid bag pumps

- Barrel discharge pumps

- The right pump for high-viscous media

Aqueous

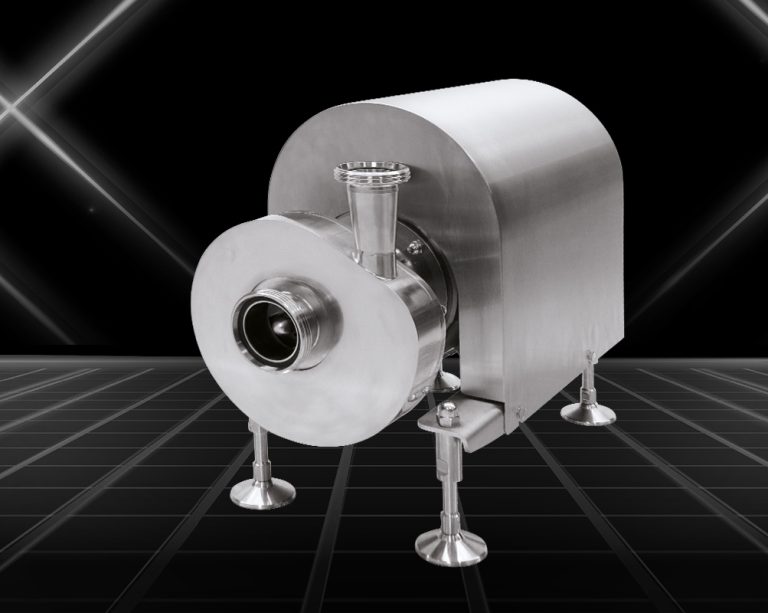

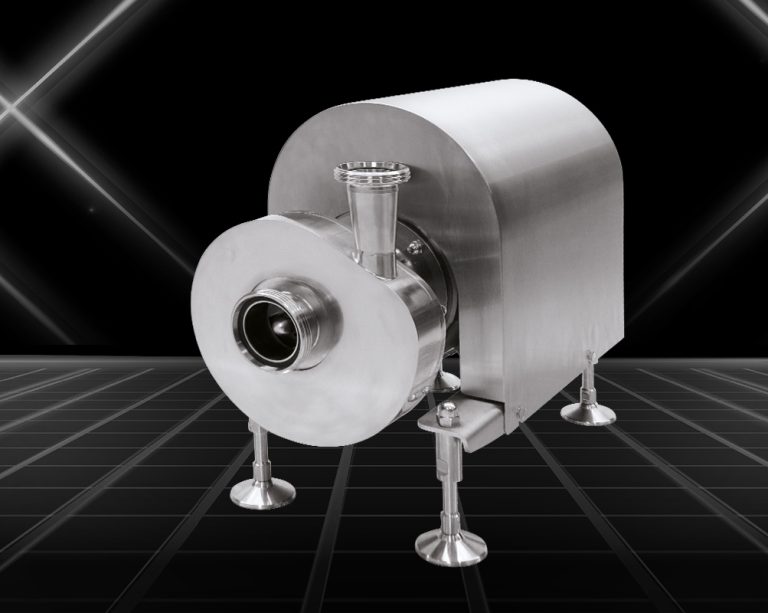

Premium centrifugal pumps for low-viscosity media

The individual customer solution

- Technical conceptOur pumps open up new vistas

- Flexibility through modularitySmall changes for maximum functionality

- Hygiene is its strengthFree of residues through self cleaning (CIP / SIP)

- Shaft sealsServiceability

- ApplicationsThe right pump for any application

#gopumping

We are ipp - specialist for rotary lobe pumps and are looking for you to join our team!

We manufacture high-tech pumps for hygienic applications. Our customers include big names from the pharmaceutical, food and cosmetics industries. ipp sets the very highest standards in product quality. This makes us the leader in technology and innovation.

How can we assist you?

Unique selling proposition - certifications

Certified according to

new ISO 9001:2015

ipp Pump Products GmbH is certified in compliance with ISO 9001:2015 in the field of development, production, sales and service of rotary lobe pumps and related pumps

European Hygienic Engineering & Design Group

The European Hygienic Engineering & Design Group (EHEDG) is an expert consortium of equipment manufacturers, experts from food producers as well as research institutes and public health authorities. The group was founded in 1989 with the principle goal to strengthen the awareness of hygienic manufacturing and packaging of food.

TÜV Nord

ipp is authorized by the TÜV NORD to restamp materials.

News from ipp Pump Products

POWTECH Technopharm 2025

The international trade fair for technologies for processing powders, solids and liquids.

September 23-25, 2025

Hall 10.0 | Booth 10-328

Aqueous centrifugal pump - ipp expands its product range

ipp Pump Products GmbH is expanding its range to include the Aqueous centrifugal pump. With its high flow rate, CIP and SIP capability and ATEX certification, it offers an ideal solution for low-viscosity media, for example in the food and pharmaceutical industries.

O-ring cover housing

O-ring cover housing